Product Description

Why choose us? What can we do for you?

♦ Founded in 2003 and experienced in the field of producing pneumatic products for 20+ years.

♦ We have large capacity, over 30000 pcs/month.

♦ Management system certification : ISO9001,CE

♦ We have 200+ technical experts for researching and developing.

♦ Sales network expands from domestic sales to all over the world.

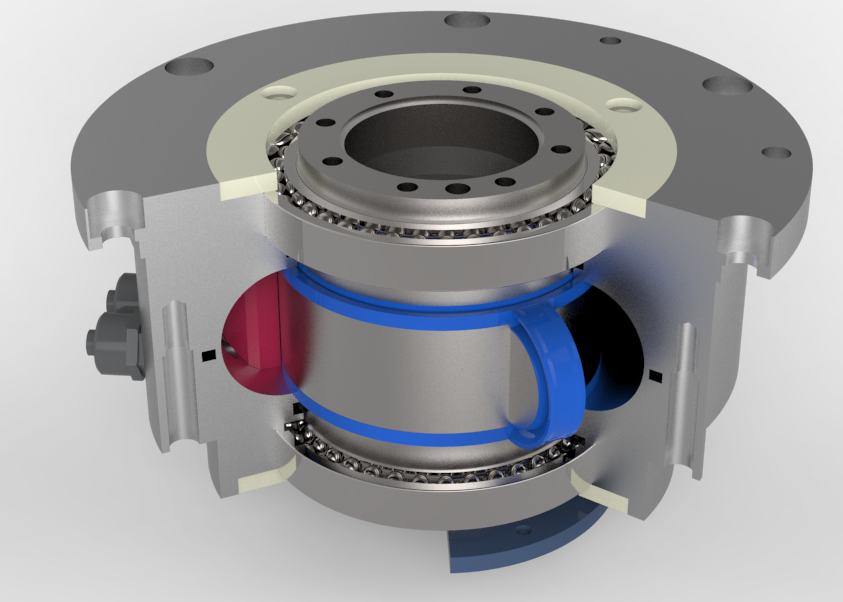

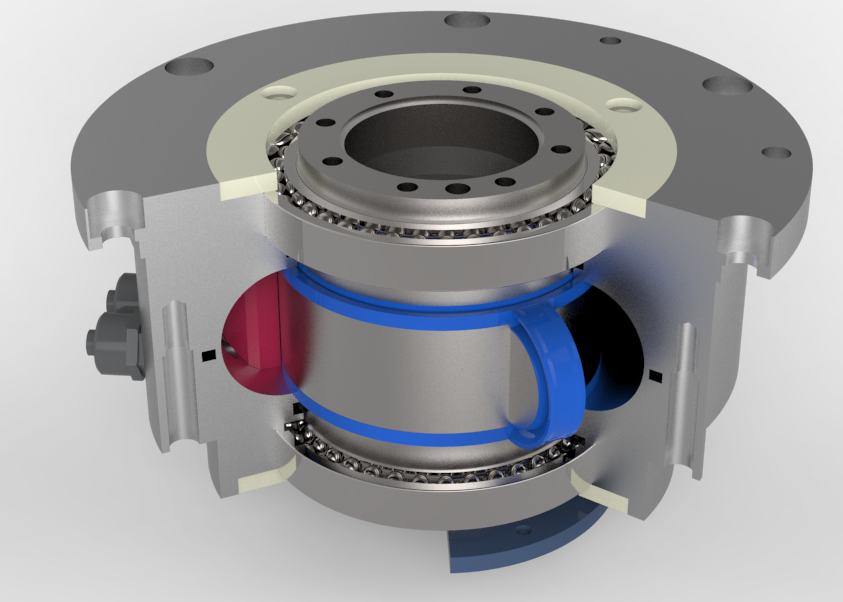

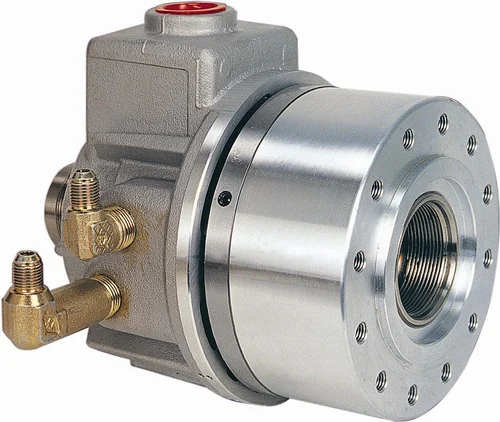

Product Show

Product Recommendation

Product Application

Company Profile

MAIN PRODUCTS

Our main products/services cover Pneumatic Valve, Pneumatic Fittings, Pneumatic Cylinders, Air Source Treatment, Pneumatic Accessories, Pneumatic Parts Actuator, Pneumatic Air dust gun, Pneumatic Hose, Pressure Gauge, Pressure Switch,

pneumatic equipment ODM & OEM services.

OUR SERVICE

In the past few years, our company absorbed and digested advanced technologies both at home and abroad.

Meanwhile, our company staffs a team of experts devoted to the development of products. Both performance

index and quality of our products reach the top level of domestic markets.

FAQ

Q1: Are factory or trading company?

A1:We are the leading manufacturer of pneumatic products who have many years experience since

2003.

Q2:What’s your main products?

A2:We mainly produce Pneumatic components,Pneumatic valves and fittings.

We provide automatic production machinery pneumatic equipment one-stop supply services!!

Q3:Can I get sample?

A3:Yes,We can offer free sample but express charge by your side.

In a word, each of your needs are of most valuable matter for us.

Q4:Do you accept OEM business?

A4:Yes.We do.

Q5:What’s the payment term?

A5:T/T,Western Union,Paypal are applicable for us.

Q6:How about the warranty?

A6:12 months under normally used.

Q7:What’s the delivery time?

A7:Normal model 2-5days,because we have ability to do the stock. For big order,it takes about 10-15days.

Q8:How to place the order?

A8:You can send us email or inquiry at Alibaba directly.

Q9:Would you have a discount if l have a large order?

A9:Yes we could offer different discount according to your order quantity.

Q10:How will you make the shipment?

A10:By sea shipment/Air/Express service.

Q11:How does your factory do the quality control?

A11:Quality is important,we always attach importance to quality control from the beginning to the end of the prodution.

Each product will be fully assembled and carefully tested before packing and shipping.

Q12:Where is the factory located?

A12:HangZhou HangZhou and welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum |

|---|---|

| Usage: | Print, Semiconductor, Automation and Control, Robot, Pneumatic Accessories |

| Structure: | Series Cylinder |

| Power: | Pneumatic |

| Standard: | Standard, Nonstandard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 30.3/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do rotary cylinders manage variations in load capacity and weight?

Rotary cylinders are designed to effectively manage variations in load capacity and weight in different applications. Here’s a detailed explanation:

1. Size and Configuration: Rotary cylinders come in various sizes and configurations to accommodate a wide range of load capacities and weights. Larger cylinders with larger piston areas can handle greater loads, while smaller cylinders are suitable for lighter loads. The selection of the appropriate cylinder size and configuration is crucial to match the specific load requirements.

2. Pressure and Force: Rotary cylinders utilize fluid pressure to generate the necessary force for rotation. By adjusting the pressure within the cylinder, the force output can be regulated to match the variations in load capacity and weight. Higher pressure is applied for heavier loads, while lower pressure is sufficient for lighter loads.

3. Load Balancing: In applications where there are variations in load capacity or weight distribution, multiple rotary cylinders can be used to balance the load. By distributing the load across multiple cylinders, the individual load capacity of each cylinder is reduced, ensuring that no single cylinder is overloaded.

4. Positioning and Center of Gravity: Proper positioning of the load and consideration of the center of gravity are important when managing variations in weight. Ensuring that the load is balanced and properly supported helps distribute the weight evenly and reduces strain on the rotary cylinder.

5. Safety Factors: When dealing with variations in load capacity and weight, it is essential to incorporate safety factors into the design and selection of rotary cylinders. Safety factors account for uncertainties and unexpected variations in the load, ensuring that the cylinder can handle occasional peak loads or weight fluctuations without compromising safety and performance.

6. Manufacturer Guidelines: Manufacturers provide load charts, technical specifications, and guidelines for their rotary cylinders. These resources outline the load capacities and weight limits for different cylinder sizes and configurations. It is crucial to consult these guidelines to ensure that the selected rotary cylinder is suitable for the specific load requirements.

7. Regular Maintenance and Inspection: Regular maintenance and inspection of rotary cylinders are necessary to ensure their continued performance and safe operation. This includes checking for any signs of wear, leaks, or damage that may affect the cylinder’s load-bearing capacity. Timely maintenance and replacement of worn components help manage variations in load capacity and weight effectively.

By considering these factors and following manufacturer recommendations, rotary cylinders can effectively manage variations in load capacity and weight in a wide range of applications.

Can rotary cylinders be applied in both mobile and stationary machinery?

Yes, rotary cylinders can be applied in both mobile and stationary machinery. Here’s a detailed explanation:

1. Mobile Machinery: Rotary cylinders find extensive use in mobile machinery, such as construction equipment, agricultural machinery, material handling equipment, and transportation vehicles. In these applications, rotary cylinders enable controlled rotational motion for various functions, including steering, lifting, tilting, opening and closing attachments, and actuating hydraulic brakes. The compact design and versatility of rotary cylinders make them well-suited for mobile machinery, where space and weight considerations are crucial.

2. Stationary Machinery: Rotary cylinders are also widely utilized in stationary machinery across various industries. They play a crucial role in applications such as industrial automation, manufacturing processes, packaging equipment, robotics, and machine tools. In stationary machinery, rotary cylinders provide controlled rotation for tasks such as part positioning, indexing, clamping, cutting, and material handling. The precise and repeatable rotational motion offered by rotary cylinders contributes to the overall efficiency and productivity of stationary machinery.

3. Versatile Mounting Options: Rotary cylinders come with versatile mounting options, allowing them to be easily integrated into different types of machinery, whether mobile or stationary. They can be mounted in various orientations and configurations to suit specific application requirements. This flexibility in mounting ensures that rotary cylinders can be effectively applied in diverse machinery designs.

4. Customization: Manufacturers offer a wide range of rotary cylinder models with different sizes, load capacities, and performance characteristics. This allows users to select the most suitable cylinder for their specific mobile or stationary machinery application. Additionally, rotary cylinders can be customized to meet specific requirements, such as stroke length, rotational speed, and mounting interfaces, further enhancing their applicability in both mobile and stationary contexts.

5. Environmental Considerations: Rotary cylinders are designed and engineered to withstand various environmental conditions encountered in both mobile and stationary machinery. They are constructed using durable materials that can withstand factors such as vibration, shock, temperature variations, and exposure to dust, moisture, or corrosive substances. This ensures reliable performance and longevity, regardless of whether the machinery is mobile or stationary.

6. Integration with Control Systems: Rotary cylinders can be seamlessly integrated into control systems, such as hydraulic or pneumatic control circuits, electronic control units (ECUs), or programmable logic controllers (PLCs). This integration allows for precise control and coordination of the rotary motion with other machine functions, enabling efficient operation and automation in both mobile and stationary machinery.

Overall, the adaptability, versatility, and performance characteristics of rotary cylinders make them suitable for application in a wide range of machinery, whether it is mobile or stationary, contributing to enhanced functionality and efficiency in various industries.

What is a rotary cylinder and how does it function in machinery?

A rotary cylinder is a type of actuator used in machinery to convert fluid power into rotational motion. Here’s a detailed explanation:

Function and Operation:

A rotary cylinder is designed to generate rotary or swinging motion in a machine or system. It consists of a cylindrical housing with an internal piston or vane mechanism. The cylinder housing is connected to the machine or system, while the piston or vane is driven by hydraulic or pneumatic pressure.

When fluid pressure is applied to the rotary cylinder, it creates a force that acts on the piston or vane. This force causes the piston or vane to move in a circular or swinging motion, resulting in rotational movement of the output shaft or mechanism connected to the cylinder. The direction and angle of rotation depend on the design and configuration of the rotary cylinder.

Types of Rotary Cylinders:

There are different types of rotary cylinders, including:

- Rack-and-pinion rotary cylinders: These cylinders use a rack and pinion mechanism to convert linear motion into rotary motion. The fluid pressure pushes the piston, which engages with the rack, causing it to rotate the pinion and generate rotary motion.

- Vane rotary cylinders: Vane cylinders use vanes or blades that are pushed outward by fluid pressure, causing the cylinder to rotate. The vanes slide in and out of slots in the rotor, creating the rotary motion.

- Gear rotary cylinders: Gear cylinders employ gears that mesh together to generate rotary motion. Fluid pressure drives the gears, causing them to rotate and transfer the motion to the output shaft.

Applications:

Rotary cylinders find applications in various machinery and industrial systems where rotational movement is required. Some common applications include:

- Rotary indexing tables

- Robotic arms and manipulators

- Material handling equipment

- Conveyor systems

- Machine tools

- Packaging machinery

Rotary cylinders offer advantages such as compact size, high torque output, and precise control over rotational motion. They can be used in both hydraulic and pneumatic systems, depending on the specific requirements of the application.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the selection, installation, and operation of rotary cylinders in machinery.

editor by Dream 2024-05-15

China manufacturer Rack Table Cylinder Pneumatic Rotary Msqb Series Msqb10A Msqb20A Msqb30A Msqb50A Msqb10r Msqb20r Pinion Original vacuum pump distributors

Product Description

Rack Table Cylinder Pneumatic Rotary MSQB Series MSQB10A MSQB20A MSQB30A MSQB50A MSQB10R MSQB20R Pinion Original

Product Description

Features:

1. Made of high quality aluminum alloy cylinder, sturdy, anti-corrosion and not easy to rust.

2. With the increase of pressure, it automatically improves the sealing performance and lasts for a long time

3. Built-in magnetic ring for magnetic switch

4. With angle adjustment unit, you can adjust the angle at 0-180°

5. The surface of the cylinder has increased the hard oxidation technology, which increases the surface hardness of the cylinder, is not easy to deform, and is durable.

6. Flexible bearing rotation and precise positioning

Specification:

| Model | MSQB-10A |

| Fluid | Air(no oil) |

| Using pressure | 1MPa with screw |

| Min using pressure | 0.1MPa |

| Environment temperature and fluid temperature |

0~60°C |

| Angle adjustment range | 0-180° |

| Swing angle | 180° |

| Cylinder inner diameter | 15mm |

| Import size | M5*0.8 |

| Weight: | Approx. 530g / 18.7oz |

Recommend products

Company Profile

Application scenarios

Certifications

FAQ

1. who are we?

We are a professional manufacturer with more than 9 years experience

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Mechanical Parts

4. why should you buy from us not from other suppliers?

1. The company integrates research and development, production and sales as an integrated business model, which greatly reduces

consumers’ purchase of finished products. 2. Short production time and quick cycle of large goods. 3. Professional after-sales

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,HKD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum |

|---|---|

| Usage: | Print, Semiconductor, Automation and Control, Robot |

| Structure: | Piston Cylinder |

| Power: | Pneumatic |

| Standard: | Standard, Nonstandard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

How do rotary cylinders manage variations in hydraulic pressure and flow rate?

Rotary cylinders are designed to effectively manage variations in hydraulic pressure and flow rate. Here’s a detailed explanation:

1. Pressure Regulation: Rotary cylinders incorporate various mechanisms to manage variations in hydraulic pressure. These mechanisms include pressure relief valves, pressure control valves, and flow control valves. Pressure relief valves are designed to protect the cylinder and the hydraulic system from excessive pressure by diverting excess fluid flow back to the reservoir. Pressure control valves, such as pressure reducing valves or pressure sequence valves, are used to regulate the pressure applied to the rotary cylinder. These valves ensure that the cylinder operates within the desired pressure range, accommodating variations in the hydraulic system.

2. Flow Control: Rotary cylinders also utilize flow control mechanisms to manage variations in hydraulic flow rate. Flow control valves, such as flow restrictors or flow control regulators, are employed to control the amount of fluid flowing into or out of the cylinder. By adjusting the opening of these valves, the flow rate can be regulated, allowing for precise control of the cylinder’s rotational speed or angular displacement. Flow control valves help manage variations in flow rate and optimize the cylinder’s performance.

3. Proportional Control: Proportional control valves are often used in conjunction with rotary cylinders to manage variations in pressure and flow rate. These valves provide continuous and precise control over the hydraulic pressure and flow by adjusting the valve opening proportionally to the input signal. Proportional control allows for real-time adjustments in response to changing operational requirements, ensuring accurate and efficient management of pressure and flow variations.

4. Feedback Devices: Rotary cylinders can incorporate feedback devices, such as pressure sensors and flow sensors, to monitor and provide feedback on the hydraulic pressure and flow rate. These sensors provide real-time information about the operating conditions, allowing for dynamic adjustments to maintain desired pressure and flow levels. Feedback devices help ensure the stability and consistency of the cylinder’s performance, even in the presence of variations in hydraulic pressure and flow rate.

5. Accumulators: In some cases, rotary cylinders can utilize hydraulic accumulators to manage variations in pressure and flow rate. Accumulators store hydraulic energy in the form of pressurized fluid, which can be released when needed to compensate for fluctuations in pressure or flow. By providing an additional source of energy, accumulators help maintain consistent pressure and flow, preventing adverse effects caused by sudden changes in hydraulic conditions.

6. System Design and Optimization: Proper system design and optimization play a crucial role in managing variations in hydraulic pressure and flow rate. This includes selecting appropriate components, sizing the hydraulic lines, and ensuring proper fluid filtration and conditioning. By designing the hydraulic system to match the requirements of the rotary cylinder and the application, variations in pressure and flow rate can be effectively managed, resulting in optimal performance.

By employing these strategies and mechanisms, rotary cylinders can effectively manage variations in hydraulic pressure and flow rate, ensuring reliable and consistent performance in a wide range of applications.

What benefits do rotary cylinders offer in terms of efficient rotary motion?

Rotary cylinders offer several benefits in terms of efficient rotary motion. Here’s a detailed explanation:

1. Compact Design: Rotary cylinders have a compact design, allowing them to be easily integrated into machinery and equipment with limited space. Their compact size ensures efficient utilization of available workspace.

2. High Torque Output: Rotary cylinders are capable of generating high torque output, making them suitable for applications that require powerful rotational force. This enables efficient operation even in heavy-duty tasks.

3. Precise Control: Rotary cylinders provide precise control over rotary motion. By adjusting the fluid pressure or flow rate, the rotational speed and position of the cylinder can be accurately controlled, allowing for precise positioning and smooth operation.

4. Quick Response Time: Rotary cylinders offer quick response times, enabling rapid and dynamic rotary motion. They can start, stop, and change direction swiftly, making them ideal for applications that require fast and precise rotary movements.

5. Versatile Mounting Options: Rotary cylinders come with versatile mounting options, allowing them to be easily mounted in different orientations to suit specific application requirements. This flexibility in mounting facilitates efficient integration into various machinery and equipment designs.

6. Energy Efficiency: Rotary cylinders are designed to be energy-efficient. They consume power only during movement, reducing energy consumption and operating costs. Additionally, the compact design of rotary cylinders minimizes friction losses, further enhancing energy efficiency.

7. Durability and Longevity: Rotary cylinders are built to be durable and withstand demanding operating conditions. They are constructed with high-quality materials and undergo rigorous testing to ensure long service life and reliable performance.

8. Wide Range of Sizes and Configurations: Rotary cylinders are available in a wide range of sizes and configurations to accommodate different application requirements. This versatility allows for efficient selection and customization based on specific load capacities, space constraints, and performance needs.

9. Compatibility with Different Fluids: Rotary cylinders are compatible with various hydraulic or pneumatic fluids, providing flexibility in choosing the most suitable fluid for the application. This compatibility ensures efficient operation and reliable performance.

10. Reduction in Manual Labor: By automating rotary motion, rotary cylinders eliminate the need for manual labor in tasks such as rotating or positioning objects. This reduces human effort, increases productivity, and minimizes the risk of repetitive strain injuries.

Overall, the efficient rotary motion provided by rotary cylinders contributes to improved productivity, enhanced control, energy efficiency, and reliable performance in a wide range of industrial applications.

How do rotary cylinders handle variations in rotation and positioning?

Rotary cylinders are designed to handle variations in rotation and positioning with precision and control. Here’s a detailed explanation:

Rotation Variations:

1. Actuation Method: Rotary cylinders use different actuation methods, such as hydraulic or pneumatic pressure, to generate rotational motion. By varying the pressure or flow rate of the fluid, the speed and torque of the rotation can be adjusted to meet specific requirements.

2. Control Valves: Control valves are used to regulate the fluid flow into and out of the rotary cylinder. By adjusting the valve settings, the rotational speed and direction can be controlled, allowing for variations in rotation as needed.

3. Feedback Systems: Some rotary cylinders incorporate feedback systems, such as position sensors or encoders, to provide real-time information about the cylinder’s rotational position. This feedback enables precise control and the ability to handle variations in rotation accurately.

Positioning Variations:

1. Stroke Adjustment: Rotary cylinders often have adjustable stroke lengths, which allow for variations in the positioning of the rotary motion. By adjusting the stroke, the range of the rotary movement can be customized to suit the specific application.

2. Positioning Guides: Rotary cylinders may feature positioning guides, such as grooves or slots, that help guide and stabilize the rotational movement. These guides ensure accurate positioning and minimize deviations or wobbling during operation.

3. Limit Switches: Limit switches or proximity sensors are sometimes used in rotary cylinders to define specific positions or limit the rotary motion within a predetermined range. These switches provide feedback to the control system, enabling precise positioning control.

4. Precision Manufacturing: Rotary cylinders are manufactured with high precision to ensure smooth and accurate rotation. The use of high-quality materials, precision machining, and tight tolerances contribute to minimizing variations in rotation and positioning.

Overall, the combination of actuation methods, control valves, feedback systems, stroke adjustment, positioning guides, limit switches, and precision manufacturing allows rotary cylinders to handle variations in rotation and positioning with the required level of accuracy and control.

It’s important to refer to the manufacturer’s specifications and guidelines for specific information on the capabilities and limitations of rotary cylinders in handling rotation and positioning variations.

editor by CX 2024-01-02

China OEM CZPT Pneumatic Rotary Table Rack & Pinion Style Cylinder Msq Series vacuum pump distributors

Product Description

Features:

Rotating Cylinders

*Easy mounting of workpiece.

*Large rolling element bearing.

*Pivoting angle adjustment range: 0~190

*With internal shock absorber.

*Movement in direction of table’s radial thrust: 0.01mm or less.

*Small size and light weight.

*Variety of installation options for space-saving.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum |

|---|---|

| Usage: | Print, Semiconductor, Automation and Control, Robot |

| Structure: | Rotary Cylinder |

| Power: | Pneumatic |

| Standard: | Standard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety considerations are important when working with machinery equipped with rotary cylinders?

Working with machinery equipped with rotary cylinders requires careful attention to safety to prevent accidents and ensure the well-being of operators and bystanders. Here are important safety considerations to keep in mind:

1. Hazard Identification: Identify potential hazards associated with the machinery and its rotary cylinders. This includes understanding the risks posed by rotating parts, high-pressure fluid systems, pinch points, and potential entanglement hazards.

2. Risk Assessment: Conduct a thorough risk assessment to evaluate the potential risks and their severity. Identify measures to mitigate risks and prioritize safety controls accordingly.

3. Safety Guards and Enclosures: Install appropriate safety guards and enclosures to prevent access to hazardous areas, such as rotating components or fluid lines. Ensure that these guards are securely in place and cannot be easily bypassed.

4. Lockout/Tagout Procedures: Develop and enforce lockout/tagout procedures to ensure that machinery equipped with rotary cylinders is properly shut down and de-energized during maintenance or repair activities. This prevents unexpected movement of the cylinders and the potential for injury.

5. Training and Competence: Provide comprehensive training to operators and maintenance personnel on the safe operation of machinery equipped with rotary cylinders. Ensure that they are competent in identifying hazards, understanding safety procedures, and implementing safe work practices.

6. Regular Maintenance and Inspections: Implement a routine maintenance program to keep the machinery and rotary cylinders in good working condition. Regularly inspect the cylinders, fluid lines, fittings, and connections for signs of wear, leaks, or damage. Replace any faulty components promptly.

7. Pressure Relief and Emergency Stop Systems: Install pressure relief valves and emergency stop systems to safely control and halt the operation of machinery in case of emergencies or unexpected events.

8. Warning Signs and Labels: Clearly display warning signs and labels to communicate potential hazards and safety instructions related to the machinery equipped with rotary cylinders. Ensure that operators and other personnel are aware of and understand these warnings.

9. Personal Protective Equipment (PPE): Provide appropriate PPE, such as safety glasses, gloves, and protective clothing, to operators and maintenance personnel. PPE should be used in accordance with relevant safety standards and risk assessments.

10. Continuous Safety Improvement: Foster a culture of continuous safety improvement by encouraging reporting of near misses, conducting regular safety audits, and addressing any identified safety concerns promptly.

It’s essential to comply with local safety regulations and industry standards specific to the machinery and applications using rotary cylinders. Additionally, consult manufacturers’ documentation and guidelines for specific safety considerations related to the rotary cylinders used in the machinery.

Can rotary cylinders be repaired or maintained when needed?

Yes, rotary cylinders can be repaired and maintained when needed to ensure their optimal performance and longevity. Here’s a detailed explanation:

1. Routine Maintenance: Regular maintenance is essential to keep rotary cylinders in good working condition. This includes tasks such as cleaning, lubrication, and inspection of components. Routine maintenance helps prevent issues and prolongs the cylinder’s lifespan.

2. Seal Replacement: Seals are critical components of rotary cylinders and may require periodic replacement due to wear or damage. Replacing seals at recommended intervals helps maintain proper sealing and prevent fluid leaks.

3. Component Replacement: In case of component failure or damage, individual components of the rotary cylinder can be replaced. This may include piston rods, seals, bearings, or other internal parts. Replacement parts should be sourced from reputable manufacturers or suppliers to ensure compatibility and quality.

4. Fluid Flush and Filter Replacement: Over time, hydraulic or pneumatic fluid used in rotary cylinders may become contaminated with particles or degrade in quality. Performing fluid flushes and replacing filters at recommended intervals helps maintain the cleanliness and performance of the fluid and extends the life of the rotary cylinder.

5. Repairs: In the event of major damage or malfunction, rotary cylinders can be repaired. Skilled technicians or authorized service centers can diagnose the issue, disassemble the cylinder, and perform repairs such as welding, re-machining, or replacing damaged parts. It is important to follow proper repair procedures and use appropriate techniques to ensure the cylinder’s integrity and performance.

6. Reconditioning: Rotary cylinders that have undergone extensive use or have been in operation for a long time may benefit from reconditioning. Reconditioning involves thorough inspection, cleaning, and refurbishment of the cylinder to restore its performance and functionality. This process may include repairs, replacement of worn components, and performance testing.

7. Documentation and Guidelines: Manufacturers provide documentation, guidelines, and technical specifications for their rotary cylinders. These resources often include information on maintenance procedures, recommended service intervals, and troubleshooting guidance. Following the manufacturer’s recommendations ensures that maintenance and repairs are carried out correctly.

It is important to note that the extent of repair and maintenance that can be performed on a rotary cylinder may vary depending on factors such as its design, complexity, and availability of spare parts. It is recommended to consult the manufacturer’s documentation or seek assistance from qualified professionals for specific repair and maintenance needs.

What is a rotary cylinder and how does it function in machinery?

A rotary cylinder is a type of actuator used in machinery to convert fluid power into rotational motion. Here’s a detailed explanation:

Function and Operation:

A rotary cylinder is designed to generate rotary or swinging motion in a machine or system. It consists of a cylindrical housing with an internal piston or vane mechanism. The cylinder housing is connected to the machine or system, while the piston or vane is driven by hydraulic or pneumatic pressure.

When fluid pressure is applied to the rotary cylinder, it creates a force that acts on the piston or vane. This force causes the piston or vane to move in a circular or swinging motion, resulting in rotational movement of the output shaft or mechanism connected to the cylinder. The direction and angle of rotation depend on the design and configuration of the rotary cylinder.

Types of Rotary Cylinders:

There are different types of rotary cylinders, including:

- Rack-and-pinion rotary cylinders: These cylinders use a rack and pinion mechanism to convert linear motion into rotary motion. The fluid pressure pushes the piston, which engages with the rack, causing it to rotate the pinion and generate rotary motion.

- Vane rotary cylinders: Vane cylinders use vanes or blades that are pushed outward by fluid pressure, causing the cylinder to rotate. The vanes slide in and out of slots in the rotor, creating the rotary motion.

- Gear rotary cylinders: Gear cylinders employ gears that mesh together to generate rotary motion. Fluid pressure drives the gears, causing them to rotate and transfer the motion to the output shaft.

Applications:

Rotary cylinders find applications in various machinery and industrial systems where rotational movement is required. Some common applications include:

- Rotary indexing tables

- Robotic arms and manipulators

- Material handling equipment

- Conveyor systems

- Machine tools

- Packaging machinery

Rotary cylinders offer advantages such as compact size, high torque output, and precise control over rotational motion. They can be used in both hydraulic and pneumatic systems, depending on the specific requirements of the application.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the selection, installation, and operation of rotary cylinders in machinery.

editor by CX 2023-12-21

China Good quality Msqb Series Rotary Table Rack&Pinion Cylinder Made in China vacuum pump connector

Product Description

Product Description

1.Rotating Cylinders.

2.Large rolling element bearing.

3.Pivoting angle adjustment range:0~190°.

4.With internal shock absorber.

5.Movement in direction of table’s radial thrust:0.01mm or less.

6.Small size and light weight.

7.Variety of installation options for space-saving

Applicable for positioning, transportation, quantitative filling, right and left displacement, flow control, etc. capable of accuracy and speedy purpose.

Specificatio

| Size | 10 | 20 | 30 | 50 | |||||

| Fluid | Air | ||||||||

| Maximum operating pressure | With adjustment bolt | 1Mpa | |||||||

| With internal shock absorber | 0.6Mpa | ||||||||

| Minimum operating pressure | Basic type | 0.1Mpa | |||||||

| High precision type | 0.2Mpa | 0.1Mpa |

|||||||

| Ambient and fluid temperature | 0 to 60ºC | ||||||||

| Cushion | Rubber buffer(standard)/With internal shock absorber(optional) | ||||||||

| Angle adjustment ranger | 0 ~ 190° | ||||||||

| Maximum rotation | 190° | ||||||||

| Stable swing time range | With adjustment bolt | 0.2~1.0s/90° | |||||||

| With internal shock absorber | 0.2~0.7s/90° | ||||||||

| Port size | Ø15 |

Ø18 | Ø21 | Ø25 | |||||

| Pipe Size | M5 x 0.8 | Rc1/8 | |||||||

| Inductive switch | D-A93 | ||||||||

HOW TO ORDER

DINENSION

PRODUCT CATALOG

APPLIANCE

PACKAGE AND DELVIERY

PAYMENT

FAQ

Q1: Are factory or trading company?

A1:We are the leading manufacturer of pneumatic products who have 10 years experience. Welcome to visit our factory

at any time.

Q2:Can I get sample?

A2:Yes,We can offer free sample but express charge by your side. In a word, each of your needs are of most valuable

matter for us.

Q3:Do you accept OEM business?

A3:Yes.We do.

Q4:What’s the payment term?

A4: T/T,Western Union,Paypal are applicable for us.

Q5: How about the warranty?

A5: 12 months under normally used.

Q6. What’s the delivery time ?

A6.. Normal model 2-5days,because we have ability to do the stock.For big order,it takes about 10-15days.

Q7: How does your factory dothe quality control?

A7: Quality is important,we always attach importance to quality control from the beginning to the end of the prodution.

Q8:Each product will be fully assembled and carefully tested before packing and shipping.

Yes, we can supply bore size 32mm to 125mm, stroke 25 to 2000mm

Q9:. We want to buy DNC series assembly kits ,aluminum tubes and piston rod,can you supply?

Yes, we can supply assembly kits,aluminum tubes and piston rod to you.

Q10:.How about the trade items you can accept?

We can accept trade items are EXW,FOB,CFR,CIF,DDP

Q11:Other ISO Standard Pneumatic Cylinders are also available for you:

DNG ISO15552 Standard cylinder

SI ISO6431 Standard cylinder

MA ISO6432 Mini cylinder

ADVU ISO6431 Compact/Thin cylinder

Our company also can provide other pneumatic cylinder as below,

1. Standard cylinder: SC/SU, MB, CA1

2. Compact cylinder: SDA, CQ2

3. Mini cylinder: MA, MAL, CJ2, CM2, CJP

4. Double-shaft cylinder: TN, CXS

5. Free installation cylinder: CU

6. Slide bearing cylinder: STM

7. Three-shaft cylinder: MGP

8. Stopper cylinder: RSQ

9. Clamp cylinder: XCK

10. Rotary cylinder: MSQ

11. Rodless cylinder: CY1

12. Air gripper: XHZ2/XHC2, XHL2, XHT2

More information and details, you can contact us and visit our website.

If you have the nonstandard products want to design, don’t hesitate to contact us.

| Material: | Aluminum |

|---|---|

| Usage: | Print, Semiconductor, Automation and Control, Robot |

| Structure: | Piston Cylinder |

| Power: | Pneumatic |

| Standard: | Standard |

| Pressure Direction: | Double-acting Cylinder |

| Customization: |

Available

|

|

|---|

What are the advantages of using rotary cylinders for rotational tasks?

Rotary cylinders offer several advantages when it comes to performing rotational tasks. Here’s a detailed explanation:

1. High Torque Output: Rotary cylinders are capable of delivering high torque output, making them suitable for tasks that require significant rotational force. They can handle heavy loads and provide the necessary power to rotate large components or objects.

2. Precise Control: Rotary cylinders provide precise control over rotational motion. By adjusting the fluid pressure or flow rate, the speed and direction of rotation can be accurately controlled, allowing for precise positioning, indexing, or synchronization with other system components.

3. Compact Size: Rotary cylinders are generally compact in size, making them suitable for applications where space is limited. Their compact design allows for easy integration into machinery and systems without occupying excessive space.

4. Versatility: Rotary cylinders can be used in both hydraulic and pneumatic systems, offering flexibility in system design and integration. They can be seamlessly integrated into existing systems or designed into new systems based on the specific requirements and available resources.

5. Wide Range of Applications: Rotary cylinders find applications in various industries and tasks that involve rotational motion. They are used in indexing tables, robotic arms, material handling equipment, conveyor systems, machine tools, packaging machinery, and more. Their versatility makes them suitable for diverse applications.

6. Reliability and Durability: Rotary cylinders are designed to withstand demanding operating conditions. They are built with robust materials and undergo rigorous testing to ensure reliability and durability. This allows them to perform consistently over extended periods, reducing downtime and maintenance requirements.

7. Cost-Effective: Rotary cylinders can offer cost-effective solutions for rotational tasks. They provide efficient energy conversion, minimizing energy consumption and operating costs. Additionally, their long service life and reliability contribute to cost savings in terms of maintenance and replacement.

It’s important to consider the specific requirements of the application and consult manufacturers’ documentation to ensure the selection and utilization of rotary cylinders that best meet the needs of the rotational tasks.

Can rotary cylinders be repaired or maintained when needed?

Yes, rotary cylinders can be repaired and maintained when needed to ensure their optimal performance and longevity. Here’s a detailed explanation:

1. Routine Maintenance: Regular maintenance is essential to keep rotary cylinders in good working condition. This includes tasks such as cleaning, lubrication, and inspection of components. Routine maintenance helps prevent issues and prolongs the cylinder’s lifespan.

2. Seal Replacement: Seals are critical components of rotary cylinders and may require periodic replacement due to wear or damage. Replacing seals at recommended intervals helps maintain proper sealing and prevent fluid leaks.

3. Component Replacement: In case of component failure or damage, individual components of the rotary cylinder can be replaced. This may include piston rods, seals, bearings, or other internal parts. Replacement parts should be sourced from reputable manufacturers or suppliers to ensure compatibility and quality.

4. Fluid Flush and Filter Replacement: Over time, hydraulic or pneumatic fluid used in rotary cylinders may become contaminated with particles or degrade in quality. Performing fluid flushes and replacing filters at recommended intervals helps maintain the cleanliness and performance of the fluid and extends the life of the rotary cylinder.

5. Repairs: In the event of major damage or malfunction, rotary cylinders can be repaired. Skilled technicians or authorized service centers can diagnose the issue, disassemble the cylinder, and perform repairs such as welding, re-machining, or replacing damaged parts. It is important to follow proper repair procedures and use appropriate techniques to ensure the cylinder’s integrity and performance.

6. Reconditioning: Rotary cylinders that have undergone extensive use or have been in operation for a long time may benefit from reconditioning. Reconditioning involves thorough inspection, cleaning, and refurbishment of the cylinder to restore its performance and functionality. This process may include repairs, replacement of worn components, and performance testing.

7. Documentation and Guidelines: Manufacturers provide documentation, guidelines, and technical specifications for their rotary cylinders. These resources often include information on maintenance procedures, recommended service intervals, and troubleshooting guidance. Following the manufacturer’s recommendations ensures that maintenance and repairs are carried out correctly.

It is important to note that the extent of repair and maintenance that can be performed on a rotary cylinder may vary depending on factors such as its design, complexity, and availability of spare parts. It is recommended to consult the manufacturer’s documentation or seek assistance from qualified professionals for specific repair and maintenance needs.

How does a rotary cylinder differ from other types of hydraulic cylinders?

A rotary cylinder differs from other types of hydraulic cylinders in several ways. Here’s a detailed explanation:

Principle of Operation:

A rotary cylinder is designed to convert fluid power into rotational motion, while other types of hydraulic cylinders primarily provide linear motion. While standard hydraulic cylinders extend and retract in a straight line, a rotary cylinder generates rotary or swinging motion.

Mechanism:

Rotary cylinders utilize different mechanisms to produce rotary motion. They may employ rack-and-pinion mechanisms, vane mechanisms, or gear mechanisms, depending on the specific design. In contrast, other types of hydraulic cylinders typically use a piston and cylinder arrangement to generate linear motion.

Direction of Motion:

Rotary cylinders produce rotational motion around a fixed axis or pivot point. The direction of rotation can be clockwise or counterclockwise, depending on the design and configuration of the cylinder. In contrast, other hydraulic cylinders provide linear motion in a straight line, either extending or retracting along the axis of the cylinder.

Applications:

Rotary cylinders are commonly used in applications where rotational movement is required, such as rotary indexing tables, robotic arms, and conveyor systems. They are suitable for tasks that involve swinging, rotating, or indexing motions. On the other hand, other types of hydraulic cylinders are used in applications that primarily require linear motion, such as lifting, pushing, or pulling.

Advantages and Disadvantages:

Rotary cylinders offer certain advantages over other types of hydraulic cylinders. They provide compact and efficient means of generating rotary motion, allowing for versatile applications. Rotary cylinders can deliver high torque output and precise control over rotational motion. However, one potential disadvantage is that they may have a more complex design and require additional components compared to standard hydraulic cylinders.

Fluid Medium:

Rotary cylinders can be powered by either hydraulic fluid or compressed air, depending on the specific design and application. Other types of hydraulic cylinders also utilize hydraulic fluid as the power medium. The choice of fluid medium depends on factors such as the desired force and speed, environmental considerations, and system requirements.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the selection, installation, and operation of rotary cylinders and other types of hydraulic cylinders for different applications.

editor by CX 2023-12-06

China Professional Hrq Airtac Type Pneumatic Pinion Angle Actuator Rotary Table Cylinder vacuum pump connector

Product Description

THRQ Air Tac Type Pneumatic Pinion Type Angle Double Acting Actuator Rotary Table Cylinder

Regarding more details. please feel free to ask Ryan.

| Model | HRQ |

| Bore size | 10,15,20,25,32mm |

| Stroke | 10-200mm |

| Material: | Aluminum |

|---|---|

| Usage: | Automation and Control |

| Structure: | Rotary Cylinder |

| Power: | Pneumatic |

| Standard: | Standard |

| Pressure Direction: | Double-acting Cylinder |

| Customization: |

Available

|

|

|---|

What safety considerations are important when working with machinery equipped with rotary cylinders?

Working with machinery equipped with rotary cylinders requires careful attention to safety to prevent accidents and ensure the well-being of operators and bystanders. Here are important safety considerations to keep in mind:

1. Hazard Identification: Identify potential hazards associated with the machinery and its rotary cylinders. This includes understanding the risks posed by rotating parts, high-pressure fluid systems, pinch points, and potential entanglement hazards.

2. Risk Assessment: Conduct a thorough risk assessment to evaluate the potential risks and their severity. Identify measures to mitigate risks and prioritize safety controls accordingly.

3. Safety Guards and Enclosures: Install appropriate safety guards and enclosures to prevent access to hazardous areas, such as rotating components or fluid lines. Ensure that these guards are securely in place and cannot be easily bypassed.

4. Lockout/Tagout Procedures: Develop and enforce lockout/tagout procedures to ensure that machinery equipped with rotary cylinders is properly shut down and de-energized during maintenance or repair activities. This prevents unexpected movement of the cylinders and the potential for injury.

5. Training and Competence: Provide comprehensive training to operators and maintenance personnel on the safe operation of machinery equipped with rotary cylinders. Ensure that they are competent in identifying hazards, understanding safety procedures, and implementing safe work practices.

6. Regular Maintenance and Inspections: Implement a routine maintenance program to keep the machinery and rotary cylinders in good working condition. Regularly inspect the cylinders, fluid lines, fittings, and connections for signs of wear, leaks, or damage. Replace any faulty components promptly.

7. Pressure Relief and Emergency Stop Systems: Install pressure relief valves and emergency stop systems to safely control and halt the operation of machinery in case of emergencies or unexpected events.

8. Warning Signs and Labels: Clearly display warning signs and labels to communicate potential hazards and safety instructions related to the machinery equipped with rotary cylinders. Ensure that operators and other personnel are aware of and understand these warnings.

9. Personal Protective Equipment (PPE): Provide appropriate PPE, such as safety glasses, gloves, and protective clothing, to operators and maintenance personnel. PPE should be used in accordance with relevant safety standards and risk assessments.

10. Continuous Safety Improvement: Foster a culture of continuous safety improvement by encouraging reporting of near misses, conducting regular safety audits, and addressing any identified safety concerns promptly.

It’s essential to comply with local safety regulations and industry standards specific to the machinery and applications using rotary cylinders. Additionally, consult manufacturers’ documentation and guidelines for specific safety considerations related to the rotary cylinders used in the machinery.

How do rotary cylinders contribute to energy-efficient equipment operation?

Rotary cylinders play a significant role in promoting energy-efficient equipment operation. Here’s a detailed explanation:

1. Power-On-Demand: Rotary cylinders operate based on fluid power, either hydraulic or pneumatic. One of the key advantages of fluid power systems is their power-on-demand capability. This means that the cylinder generates force and consumes energy only when necessary to perform a specific task. When the task is completed, the fluid flow to the cylinder can be shut off, resulting in energy savings compared to continuously running mechanical systems.

2. Efficient Force Conversion: Rotary cylinders efficiently convert fluid power into rotary motion. They can generate high torque, enabling them to perform tasks requiring substantial rotational force. The efficient force conversion minimizes energy losses during operation, allowing for effective utilization of input energy to achieve desired movements and work output.

3. Compact Design: Rotary cylinders are often designed to be compact and lightweight. This design approach reduces the overall weight and inertia of the equipment, resulting in energy savings. The reduced weight requires less energy to accelerate and decelerate the moving parts of the equipment, leading to improved energy efficiency.

4. Precise Control: Rotary cylinders offer precise control over the rotational motion. The ability to control speed, acceleration, and position with accuracy allows for optimized equipment operation. By fine-tuning the control parameters, energy consumption can be minimized while still achieving the desired performance. This precise control contributes to energy-efficient operation by avoiding unnecessary energy wastage.

5. Integration with Control Systems: Rotary cylinders can be seamlessly integrated into control systems such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems. These control systems enable advanced algorithms and optimization techniques to be applied to the operation of rotary cylinders. By optimizing the control signals and adjusting parameters in real-time, energy consumption can be further reduced while maintaining the required functionality.

6. Energy Recovery: In certain applications, rotary cylinders can incorporate energy recovery systems. These systems capture and utilize the energy released during deceleration or load lowering. For example, in hydraulic systems, energy recovery can be achieved through the use of regenerative valves or accumulators, which store and reuse the energy that would otherwise be dissipated as heat. By recovering and reusing energy, overall energy efficiency is improved.

7. System Optimization: Rotary cylinders are part of larger systems and equipment. By considering the overall system design and optimizing the interaction between components, energy-efficient operation can be achieved. This may involve optimizing the sizing and selection of rotary cylinders, reducing friction and leakage losses, implementing efficient fluid distribution systems, and employing energy-efficient control strategies.

8. Monitoring and Maintenance: Regular monitoring and maintenance of rotary cylinders contribute to energy-efficient equipment operation. By detecting and addressing issues such as leaks, wear, or misalignment, the performance and efficiency of the cylinders can be maintained. Proper lubrication and alignment also reduce energy losses and ensure smooth operation.

By incorporating these features and considerations, rotary cylinders contribute to energy-efficient equipment operation, reducing energy consumption, and promoting sustainability in various industries.

How do rotary cylinders handle variations in rotation and positioning?

Rotary cylinders are designed to handle variations in rotation and positioning with precision and control. Here’s a detailed explanation:

Rotation Variations:

1. Actuation Method: Rotary cylinders use different actuation methods, such as hydraulic or pneumatic pressure, to generate rotational motion. By varying the pressure or flow rate of the fluid, the speed and torque of the rotation can be adjusted to meet specific requirements.

2. Control Valves: Control valves are used to regulate the fluid flow into and out of the rotary cylinder. By adjusting the valve settings, the rotational speed and direction can be controlled, allowing for variations in rotation as needed.

3. Feedback Systems: Some rotary cylinders incorporate feedback systems, such as position sensors or encoders, to provide real-time information about the cylinder’s rotational position. This feedback enables precise control and the ability to handle variations in rotation accurately.

Positioning Variations:

1. Stroke Adjustment: Rotary cylinders often have adjustable stroke lengths, which allow for variations in the positioning of the rotary motion. By adjusting the stroke, the range of the rotary movement can be customized to suit the specific application.

2. Positioning Guides: Rotary cylinders may feature positioning guides, such as grooves or slots, that help guide and stabilize the rotational movement. These guides ensure accurate positioning and minimize deviations or wobbling during operation.

3. Limit Switches: Limit switches or proximity sensors are sometimes used in rotary cylinders to define specific positions or limit the rotary motion within a predetermined range. These switches provide feedback to the control system, enabling precise positioning control.

4. Precision Manufacturing: Rotary cylinders are manufactured with high precision to ensure smooth and accurate rotation. The use of high-quality materials, precision machining, and tight tolerances contribute to minimizing variations in rotation and positioning.

Overall, the combination of actuation methods, control valves, feedback systems, stroke adjustment, positioning guides, limit switches, and precision manufacturing allows rotary cylinders to handle variations in rotation and positioning with the required level of accuracy and control.

It’s important to refer to the manufacturer’s specifications and guidelines for specific information on the capabilities and limitations of rotary cylinders in handling rotation and positioning variations.

editor by CX 2023-12-05

China high quality CZPT Rotary Table Cylinder Msq Msq10r Air Rotary Cylinder manufacturer

Product Description

Product Description

FEATURES:

1.Integrated table and rotary actuator

2.Equipped with an angle adjustment mechanism

3.Easy alignment when mounting the load and the body

4.Built-in shock absorber type and external absorber type are selectable.

| Bore Size(mm) | 10 | 20 | 30 | 50 | 70 | 100 | 200 | |

| Working Medium | Clean Air | |||||||

| Working Pressure Range | With Adjustable Angle Screw:0.1~1.0Mpa With Shock Absorber:0.1~0.6Mpa | |||||||

| Cushion Type | Cushion Rubber Cushion(Standard) / shock Absorber(Coptional) | |||||||

| Allowed Power | With Adjustable Angel Screw | 0.007J | 0.571J | 0.048J | 0.081J | 0.24J | 0.32J | 0.56J |

| With Shock Absorber | 0.039J | 0.116J | 0.294J | 1.1J | 1.6J | 2.9J | ||

| Angle Adjustable Range | 0~190° | |||||||

| Steady Swing Time Range | 0.2~1.0s/90° | 0.2~1.5s/90° | 0.2~2.0s/90° | 0.2~2.5s/90° | ||||

| 0.2~0.7s/90° | 0.2~1.0s/90° | |||||||

| Piston Diameter | φ15 | φ18 | φ21 | φ25 | φ28 | φ32 | φ40 | |

| Port Size | M5*0.8 | G1/8 | ||||||

Product Parameters

Company Profile

Packaging & Shipping

We always believe:

There are no wrong customers,only poor services!!

| Material: | Aluminum |

|---|---|

| Usage: | Print, Automation and Control, Robot |

| Structure: | Rotary Cylinder |

| Power: | Pneumatic |

| Standard: | Standard, Nonstandard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can rotary cylinders be employed in material handling equipment for rotational tasks?

Yes, rotary cylinders can be employed in material handling equipment for rotational tasks. Here’s a detailed explanation:

Material handling equipment encompasses a wide range of machinery used for the movement, positioning, and manipulation of materials in various industries. Rotary cylinders are well-suited for performing rotational tasks in material handling applications. Here’s how they are employed:

1. Rotational Motion Generation: Rotary cylinders convert fluid power, either hydraulic or pneumatic, into rotary motion. They can provide the necessary torque and rotational force to rotate or manipulate materials. By controlling the fluid flow to the cylinder, the rotational motion can be precisely regulated, allowing for controlled and accurate handling of materials.

2. Load Manipulation: Rotary cylinders can be used to manipulate loads by rotating them to a desired position or orientation. For example, in manufacturing processes, rotary cylinders can be employed to rotate workpieces for machining, assembly, or inspection purposes. In warehouse or logistics applications, they can be used to rotate pallets, containers, or other materials for loading, unloading, or sorting operations.

3. Angular Positioning: Rotary cylinders enable angular positioning of materials with high accuracy. They can rotate objects to specific angles or index them at precise intervals. This capability is crucial in applications that require precise alignment or positioning of materials, such as aligning components for assembly or positioning items on conveyor systems.

4. Synchronization with Other Equipment: Rotary cylinders can be seamlessly integrated with other material handling equipment to achieve synchronized rotational tasks. For example, they can be coupled with conveyors, robotic arms, or grippers to rotate or position materials as part of a coordinated handling process. This integration enhances the overall efficiency and productivity of material handling operations.

5. Control and Adjustability: Rotary cylinders offer precise control over the rotational motion, allowing for adjustments based on the specific requirements of the material handling task. The rotational speed, acceleration, and stopping position can be accurately controlled, ensuring safe and efficient material manipulation. This control and adjustability contribute to optimized handling operations and improved productivity.

6. Compact and Lightweight Design: Rotary cylinders are often designed to be compact and lightweight, making them suitable for integration into material handling equipment. Their compact size allows for efficient use of space, while their lightweight nature reduces the overall weight of the equipment. This design characteristic facilitates faster response times, reduces inertia, and enhances the overall performance and maneuverability of the material handling equipment.

7. Customization: Manufacturers offer a wide range of rotary cylinder models with different sizes, load capacities, and performance characteristics. This allows users to select the most suitable cylinder for their specific material handling application. Customization options further enhance the ability to tailor the cylinder’s performance to meet the rotational requirements of different materials and tasks.

8. Safety Features: Rotary cylinders can incorporate safety features to ensure secure material handling. These features may include position sensing devices, limit switches, or torque sensors that detect abnormal conditions or prevent excessive forces during rotation. Safety mechanisms help protect the materials being handled, prevent damage to the equipment, and ensure the safety of operators.

By incorporating these features and considerations, rotary cylinders serve as valuable components in material handling equipment, enabling efficient and precise rotational tasks for a wide range of materials and applications.

How do rotary cylinders contribute to controlled and precise rotation?

Rotary cylinders play a significant role in achieving controlled and precise rotation in various applications. Here’s a detailed explanation:

1. Fluid-Powered Actuation: Rotary cylinders utilize hydraulic or pneumatic fluid to generate rotary motion. By controlling the flow of fluid into and out of the cylinder, the rotation can be precisely regulated. This fluid-powered actuation allows for smooth and controlled rotation with high accuracy.

2. Adjustable Pressure and Flow: The pressure and flow of the fluid supplied to the rotary cylinder can be adjusted to control the rotational speed and torque. By varying the pressure or flow rate, the cylinder’s rotational characteristics can be fine-tuned to achieve the desired level of control and precision.

3. Position Feedback Devices: To enhance control and precision, rotary cylinders can be equipped with position feedback devices such as rotary encoders or potentiometers. These devices provide real-time feedback on the cylinder’s rotational position, allowing for accurate positioning and control over the rotation.

4. Servo Control Systems: Rotary cylinders can be integrated into servo control systems, which offer advanced control capabilities. Servo systems use feedback signals to continuously monitor and adjust the cylinder’s position, speed, and torque. This closed-loop control mechanism enables precise rotation and ensures the desired positional accuracy is maintained.

5. Speed and Acceleration Control: Rotary cylinders provide control over the rotation speed and acceleration. By adjusting the fluid flow rate or pressure, the rotational velocity and acceleration can be precisely controlled. This feature is particularly beneficial in applications that require smooth and gradual acceleration or deceleration to prevent jerky movements or damage to the equipment.

6. Positioning Accuracy: Rotary cylinders offer excellent positioning accuracy, allowing for precise angular displacement. By combining precise control of fluid flow and feedback from position sensors, the cylinder can accurately reach and maintain specific rotational positions. This level of positioning accuracy is crucial in applications that require precise alignment or synchronization with other components or processes.

7. Repeatability: Rotary cylinders exhibit high repeatability, meaning they can repeatedly achieve the same rotational position with minimal variation. This characteristic is essential in tasks that require consistent and repeatable rotational movements, such as assembly, indexing, or machining processes.

8. Compatibility with Control Systems: Rotary cylinders can be seamlessly integrated into various control systems, such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems. This compatibility enables precise coordination and synchronization of rotary motion with other machine operations, ensuring controlled and precise rotation within the overall system.

9. Compact and Lightweight Design: Rotary cylinders are often designed to be compact and lightweight, reducing rotational inertia and enabling faster response times. This design characteristic contributes to the overall control and precision of the rotation.

10. Customization and Optimization: Manufacturers offer a wide range of rotary cylinder models with different performance characteristics. This allows users to select the most suitable cylinder based on their specific control and precision requirements. Customization options further enhance the ability to tailor the cylinder’s performance to meet specific application needs.

By incorporating these features and technologies, rotary cylinders contribute to controlled and precise rotation in a wide range of industrial and automation applications.

What industries commonly use rotary cylinders in their equipment?

Rotary cylinders find applications in various industries where rotational motion is required. Here’s a detailed explanation:

Industries:

1. Manufacturing and Automation: Rotary cylinders are extensively used in manufacturing and automation industries. They are employed in machinery and equipment for tasks such as part rotation, indexing, material handling, and robotic arm movement.

2. Packaging: The packaging industry utilizes rotary cylinders in packaging machinery for tasks such as container rotation, labeling, sealing, and filling processes.

3. Automotive: In the automotive industry, rotary cylinders are utilized in assembly lines, robotic welding, painting systems, and automated material handling systems.

4. Aerospace and Defense: Rotary cylinders are employed in aerospace and defense applications for tasks such as actuating control surfaces, robotic arm movement, precision machining, and testing equipment.

5. Food and Beverage: The food and beverage industry uses rotary cylinders in equipment for tasks such as product sorting, packaging, labeling, and filling processes.

6. Material Handling and Logistics: Rotary cylinders are used in material handling and logistics equipment, including conveyor systems, lifts, cranes, and automated storage and retrieval systems.

7. Printing and Paper: The printing and paper industry utilizes rotary cylinders in printing presses, paper handling systems, cutting and folding machines, and other equipment requiring precise rotation and movement.

8. Textile and Apparel: Rotary cylinders are employed in textile and apparel machinery for tasks such as fabric winding, dyeing, printing, cutting, and sewing operations.

9. Energy and Utilities: The energy and utilities sector uses rotary cylinders in equipment such as turbines, valves, actuators, and control systems for power generation, water treatment, and oil and gas processing.

10. Medical and Pharmaceutical: Rotary cylinders find applications in medical and pharmaceutical equipment for tasks such as precision positioning, robotic surgery, packaging, and laboratory automation.

These are just a few examples, and rotary cylinders can be found in numerous other industries and applications where rotational or swinging motion is required.

It’s important to consult industry-specific guidelines and requirements for the proper selection, integration, and maintenance of rotary cylinders in equipment.

editor by CX 2023-12-05

China manufacturer Zrq Series CZPT Rotating Air Cylinder Rotary Table Pneumatic Cylinder with Hot selling

Product Description

Product Description

ZRQ CYLINDER SERIES

Pcoduct Features

1.Rack and pinion design, stable functioning.

2.Double cylinder structure, double output could be achieved.

3.The manufacturing precision of working platform is high, and is easy for installation , and is of precise orientation.

4.The center of working platform has a through hole, and pipe can belocated and passed through this hole;

5.Xihu (West Lake) Dis. hole is designed on the both side of the cylinder body (10~200) or undersurface(2~7), which is simply to install.

6.Two modes of buffer could be chosen, adjustment bolt buffer and internalshock absorber, the maximum buffer energy of internal shock absorber is 3-5 times that of adjustment bolt buffer.

Specification parameters

| Cylinderbore(mm) 10 20 30 50 70 100 200 | ||||||||

| Mode of movement | Double acting type | |||||||

| Working medium | Air(filtered by more than 40μm) | |||||||

| The pressure range of use | 0.15~0.7MP: | |||||||

| Proof pressure | 1.2MPa | |||||||

| Operating temperature | -5~70ºC | |||||||

| Rotation angle range | 0~190° | |||||||

| Repeatability | With adjusting screws | 0.2° | ||||||

| With internal Shock absorber | 0.05° | |||||||

| The theoretical torque (Nm)is 0.5MPa | 1.1 | 1.2 | 2.5 | 5 | 7.5 | 11 | 22 | |

| Buffer form | With adjusting screws | Rubber bumper | ||||||

| With internal Shock absorber | Shock absorber | |||||||

| Connection diameter | Front end interface | M5×0.8 | G1/8 | |||||

| Side interface | M5x0.8 | |||||||

Standard stroke parameters

Product Parameters

| Material: | Aluminum |

|---|---|

| Usage: | Automation and Control |

| Structure: | General Cylinder |

| Power: | Pneumatic |

| Standard: | Standard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do rotary cylinders manage variations in hydraulic pressure and flow rate?

Rotary cylinders are designed to effectively manage variations in hydraulic pressure and flow rate. Here’s a detailed explanation:

1. Pressure Regulation: Rotary cylinders incorporate various mechanisms to manage variations in hydraulic pressure. These mechanisms include pressure relief valves, pressure control valves, and flow control valves. Pressure relief valves are designed to protect the cylinder and the hydraulic system from excessive pressure by diverting excess fluid flow back to the reservoir. Pressure control valves, such as pressure reducing valves or pressure sequence valves, are used to regulate the pressure applied to the rotary cylinder. These valves ensure that the cylinder operates within the desired pressure range, accommodating variations in the hydraulic system.

2. Flow Control: Rotary cylinders also utilize flow control mechanisms to manage variations in hydraulic flow rate. Flow control valves, such as flow restrictors or flow control regulators, are employed to control the amount of fluid flowing into or out of the cylinder. By adjusting the opening of these valves, the flow rate can be regulated, allowing for precise control of the cylinder’s rotational speed or angular displacement. Flow control valves help manage variations in flow rate and optimize the cylinder’s performance.

3. Proportional Control: Proportional control valves are often used in conjunction with rotary cylinders to manage variations in pressure and flow rate. These valves provide continuous and precise control over the hydraulic pressure and flow by adjusting the valve opening proportionally to the input signal. Proportional control allows for real-time adjustments in response to changing operational requirements, ensuring accurate and efficient management of pressure and flow variations.

4. Feedback Devices: Rotary cylinders can incorporate feedback devices, such as pressure sensors and flow sensors, to monitor and provide feedback on the hydraulic pressure and flow rate. These sensors provide real-time information about the operating conditions, allowing for dynamic adjustments to maintain desired pressure and flow levels. Feedback devices help ensure the stability and consistency of the cylinder’s performance, even in the presence of variations in hydraulic pressure and flow rate.

5. Accumulators: In some cases, rotary cylinders can utilize hydraulic accumulators to manage variations in pressure and flow rate. Accumulators store hydraulic energy in the form of pressurized fluid, which can be released when needed to compensate for fluctuations in pressure or flow. By providing an additional source of energy, accumulators help maintain consistent pressure and flow, preventing adverse effects caused by sudden changes in hydraulic conditions.

6. System Design and Optimization: Proper system design and optimization play a crucial role in managing variations in hydraulic pressure and flow rate. This includes selecting appropriate components, sizing the hydraulic lines, and ensuring proper fluid filtration and conditioning. By designing the hydraulic system to match the requirements of the rotary cylinder and the application, variations in pressure and flow rate can be effectively managed, resulting in optimal performance.

By employing these strategies and mechanisms, rotary cylinders can effectively manage variations in hydraulic pressure and flow rate, ensuring reliable and consistent performance in a wide range of applications.

How do rotary cylinders contribute to energy-efficient equipment operation?

Rotary cylinders play a significant role in promoting energy-efficient equipment operation. Here’s a detailed explanation:

1. Power-On-Demand: Rotary cylinders operate based on fluid power, either hydraulic or pneumatic. One of the key advantages of fluid power systems is their power-on-demand capability. This means that the cylinder generates force and consumes energy only when necessary to perform a specific task. When the task is completed, the fluid flow to the cylinder can be shut off, resulting in energy savings compared to continuously running mechanical systems.

2. Efficient Force Conversion: Rotary cylinders efficiently convert fluid power into rotary motion. They can generate high torque, enabling them to perform tasks requiring substantial rotational force. The efficient force conversion minimizes energy losses during operation, allowing for effective utilization of input energy to achieve desired movements and work output.

3. Compact Design: Rotary cylinders are often designed to be compact and lightweight. This design approach reduces the overall weight and inertia of the equipment, resulting in energy savings. The reduced weight requires less energy to accelerate and decelerate the moving parts of the equipment, leading to improved energy efficiency.

4. Precise Control: Rotary cylinders offer precise control over the rotational motion. The ability to control speed, acceleration, and position with accuracy allows for optimized equipment operation. By fine-tuning the control parameters, energy consumption can be minimized while still achieving the desired performance. This precise control contributes to energy-efficient operation by avoiding unnecessary energy wastage.

5. Integration with Control Systems: Rotary cylinders can be seamlessly integrated into control systems such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems. These control systems enable advanced algorithms and optimization techniques to be applied to the operation of rotary cylinders. By optimizing the control signals and adjusting parameters in real-time, energy consumption can be further reduced while maintaining the required functionality.

6. Energy Recovery: In certain applications, rotary cylinders can incorporate energy recovery systems. These systems capture and utilize the energy released during deceleration or load lowering. For example, in hydraulic systems, energy recovery can be achieved through the use of regenerative valves or accumulators, which store and reuse the energy that would otherwise be dissipated as heat. By recovering and reusing energy, overall energy efficiency is improved.

7. System Optimization: Rotary cylinders are part of larger systems and equipment. By considering the overall system design and optimizing the interaction between components, energy-efficient operation can be achieved. This may involve optimizing the sizing and selection of rotary cylinders, reducing friction and leakage losses, implementing efficient fluid distribution systems, and employing energy-efficient control strategies.

8. Monitoring and Maintenance: Regular monitoring and maintenance of rotary cylinders contribute to energy-efficient equipment operation. By detecting and addressing issues such as leaks, wear, or misalignment, the performance and efficiency of the cylinders can be maintained. Proper lubrication and alignment also reduce energy losses and ensure smooth operation.

By incorporating these features and considerations, rotary cylinders contribute to energy-efficient equipment operation, reducing energy consumption, and promoting sustainability in various industries.

How do rotary cylinders handle variations in rotation and positioning?

Rotary cylinders are designed to handle variations in rotation and positioning with precision and control. Here’s a detailed explanation:

Rotation Variations:

1. Actuation Method: Rotary cylinders use different actuation methods, such as hydraulic or pneumatic pressure, to generate rotational motion. By varying the pressure or flow rate of the fluid, the speed and torque of the rotation can be adjusted to meet specific requirements.

2. Control Valves: Control valves are used to regulate the fluid flow into and out of the rotary cylinder. By adjusting the valve settings, the rotational speed and direction can be controlled, allowing for variations in rotation as needed.