Product Description

- About GD Macinery Co.,Ltd

GD Machinery Co., Ltd. is a specialized manufacturer and trader with main products: hydraulic cylinders, hydraulic power units, hydraulic manifolds-blocks, hydraulic flanges,pneumatic cylinders and custom-made components and parts, like industrial valves.

Our sales markets have covered our sales markets have covered North America, Europe, Australia and Japan.

WELDED HYDRAULIC CYLIDNERS

Specificattions:

- Please review our production processes:

Packaging

We use metal case,plywood case /carton or as Customer’s requirements

Hydraulic cylinders can be built according to your drawings or technical requirement.

Sample order are acceptable.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | RoHS, ISO9001 |

|---|---|

| Pressure: | Medium Pressure |

| Work Temperature: | Normal Temperature |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do rotary cylinders manage variations in load capacity and weight?

Rotary cylinders are designed to effectively manage variations in load capacity and weight in different applications. Here’s a detailed explanation:

1. Size and Configuration: Rotary cylinders come in various sizes and configurations to accommodate a wide range of load capacities and weights. Larger cylinders with larger piston areas can handle greater loads, while smaller cylinders are suitable for lighter loads. The selection of the appropriate cylinder size and configuration is crucial to match the specific load requirements.

2. Pressure and Force: Rotary cylinders utilize fluid pressure to generate the necessary force for rotation. By adjusting the pressure within the cylinder, the force output can be regulated to match the variations in load capacity and weight. Higher pressure is applied for heavier loads, while lower pressure is sufficient for lighter loads.

3. Load Balancing: In applications where there are variations in load capacity or weight distribution, multiple rotary cylinders can be used to balance the load. By distributing the load across multiple cylinders, the individual load capacity of each cylinder is reduced, ensuring that no single cylinder is overloaded.

4. Positioning and Center of Gravity: Proper positioning of the load and consideration of the center of gravity are important when managing variations in weight. Ensuring that the load is balanced and properly supported helps distribute the weight evenly and reduces strain on the rotary cylinder.

5. Safety Factors: When dealing with variations in load capacity and weight, it is essential to incorporate safety factors into the design and selection of rotary cylinders. Safety factors account for uncertainties and unexpected variations in the load, ensuring that the cylinder can handle occasional peak loads or weight fluctuations without compromising safety and performance.

6. Manufacturer Guidelines: Manufacturers provide load charts, technical specifications, and guidelines for their rotary cylinders. These resources outline the load capacities and weight limits for different cylinder sizes and configurations. It is crucial to consult these guidelines to ensure that the selected rotary cylinder is suitable for the specific load requirements.

7. Regular Maintenance and Inspection: Regular maintenance and inspection of rotary cylinders are necessary to ensure their continued performance and safe operation. This includes checking for any signs of wear, leaks, or damage that may affect the cylinder’s load-bearing capacity. Timely maintenance and replacement of worn components help manage variations in load capacity and weight effectively.

By considering these factors and following manufacturer recommendations, rotary cylinders can effectively manage variations in load capacity and weight in a wide range of applications.

How do rotary cylinders handle variations in environmental conditions?

Rotary cylinders are designed to handle variations in environmental conditions encountered in different applications. Here’s a detailed explanation:

1. Robust Construction: Rotary cylinders are constructed using durable materials such as high-grade metals, alloys, and seals that can withstand harsh environmental conditions. They are designed to resist factors like vibration, shock, temperature variations, dust, moisture, and exposure to corrosive substances. The robust construction ensures that rotary cylinders can operate reliably and maintain performance integrity in challenging environments.

2. Sealing Mechanisms: Rotary cylinders incorporate sealing mechanisms to prevent the ingress of contaminants such as dirt, water, and chemicals. These sealing mechanisms include O-rings, wipers, and lip seals, which create a barrier between the cylinder’s internal components and the external environment. Effective sealing helps protect the cylinder’s internal parts, ensuring smooth operation and preventing damage caused by environmental factors.

3. Lubrication Systems: Proper lubrication is essential for the smooth functioning of rotary cylinders. They are equipped with lubrication systems that deliver lubricants to critical moving parts, reducing friction, wear, and the risk of corrosion. Lubrication systems can be designed to operate under different environmental conditions, ensuring optimal performance and longevity of the cylinder.

4. Temperature Compensation: Rotary cylinders can be designed with temperature compensation features to accommodate variations in operating temperatures. When exposed to high or low temperatures, materials can expand or contract, potentially affecting the cylinder’s performance. Temperature compensation mechanisms, such as thermal expansion compensation or heat dissipation features, help maintain the cylinder’s dimensional stability and performance in different temperature conditions.

5. Protective Coatings: In environments where there is a high risk of corrosion or abrasion, rotary cylinders can be coated with protective layers or treatments. These coatings, such as corrosion-resistant plating, powder coatings, or specialized coatings for specific applications, provide an additional barrier against environmental factors and extend the cylinder’s lifespan.

6. Environmental Testing: Manufacturers subject rotary cylinders to rigorous testing procedures to ensure their performance and reliability under various environmental conditions. These tests may include temperature cycling, humidity exposure, dust and particle ingress testing, vibration testing, and salt spray testing. Environmental testing helps identify potential weaknesses and allows for improvements in design and materials to enhance the cylinder’s ability to handle environmental variations.

7. IP Ratings: In industrial applications, rotary cylinders are often assigned an Ingress Protection (IP) rating. IP ratings indicate the level of protection against solid particles (first digit) and moisture (second digit) that the cylinder can withstand. Higher IP ratings signify greater resistance to environmental factors. Users can select rotary cylinders with appropriate IP ratings based on the specific environmental conditions of their application.

8. Application-Specific Designs: Depending on the industry and application requirements, rotary cylinders can be designed with specific environmental considerations in mind. For example, in marine or offshore applications, cylinders can be corrosion-resistant and designed to withstand saltwater exposure. In dusty environments, additional filtration systems can be incorporated to prevent dust ingress. Customized designs allow rotary cylinders to handle variations in environmental conditions effectively.

By incorporating these features and design considerations, rotary cylinders can effectively handle variations in environmental conditions, ensuring reliable performance and longevity in diverse applications.

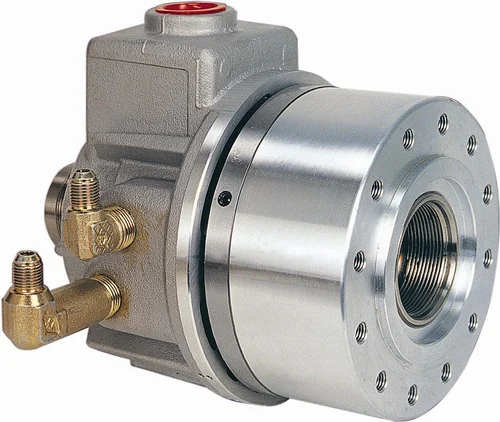

What are the key components and design features of a rotary cylinder?

A rotary cylinder consists of several key components and design features that enable its operation. Here’s a detailed explanation:

Key Components:

1. Housing: The housing is a cylindrical structure that encloses the internal components of the rotary cylinder. It provides support and protection to the internal mechanisms.

2. Piston or Vane: The piston or vane is the component that converts fluid pressure into rotary motion. In rack-and-pinion rotary cylinders, the piston engages with a rack to generate rotation. In vane or gear rotary cylinders, the piston or vane is responsible for creating the rotary motion directly.

3. Seals: Seals are used to prevent leakage of fluid and maintain pressure within the cylinder. They are typically made of rubber or other materials that provide a tight and reliable seal.

4. Bearings: Bearings are used to support the rotating components and reduce friction. They ensure smooth and efficient movement of the piston or vane within the cylinder.

Design Features:

1. Mechanism Type: Rotary cylinders can have different mechanism types, such as rack-and-pinion, vane, or gear mechanisms. The choice of mechanism depends on factors such as the required torque, speed, and application requirements.

2. Mounting Options: Rotary cylinders may have various mounting options to facilitate their installation and integration into different machinery or systems. Common mounting options include flange mounts, foot mounts, and trunnion mounts.

3. Fluid Connections: Rotary cylinders require fluid connections to supply hydraulic fluid or compressed air for their operation. These connections allow the cylinder to receive and release the fluid as needed to generate the rotary motion.

4. Motion Control: Some rotary cylinders may feature additional components for motion control, such as position sensors or limit switches. These components allow for precise control and monitoring of the rotary motion, enabling automation and system feedback.

5. Size and Capacity: Rotary cylinders come in various sizes and capacities to accommodate different application requirements. The size and capacity of a rotary cylinder determine its torque output, speed capabilities, and overall performance characteristics.

6. Material Selection: The materials used in the construction of a rotary cylinder are chosen based on factors such as strength, durability, and compatibility with the operating environment. Common materials include steel, aluminum, and various alloys.

Overall, the key components and design features of a rotary cylinder work together to convert fluid power into rotary motion efficiently and reliably. These components and features ensure smooth operation, precise control, and the ability to meet the demands of specific applications.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the components, design, and maintenance of rotary cylinders.

editor by Dream 2024-04-26