Product Description

Product Description

other hot products

| No. | Size | Type | OEM | |

| No | Size | No | Size | |

| 1 | 14X22X4.5/5.5 | 22 | 85X99X8/11 | |

| 2 | 14X22X5/7 | 23 | 90X104X8/11 | |

| 3 | 19X31X6/9 | 24 | 95X109X8/11 | |

| 4 | 20X32X6/9 | 25 | 100X114X8/11 | |

| 5 | 22X32X6/9 | 26 | 105X121X9/12 | |

| 6 | 25X37X6/9 | 27 | 110X126X9/12 | |

| 7 | 28X40X6/9 | 28 | 115X131X9/12 | |

| 8 | 30X42X6/9 | 29 | 120X136X9/12 | |

| 9 | 32X44X7/10 | 30 | 125X141X9/12 | |

| 10 | 35X47X7/10 | 31 | 130X146X9/12 | |

| 11 | 40X52X7/10 | 32 | 140X160X10/14 | |

| 12 | 45X57X7/10 | 33 | 145X165X10/14 | |

| 13 | 50X62X7/10 | 34 | 150X 170X10/14 | |

| 14 | 50X64X8/11 | 35 | 160X180X10/14 | |

| 15 | 55X69X8/11 | 36 | 170X190X10/14 | |

| 16 | 60X74X8/11 | 37 | 180X200X10/14 | |

| 17 | 65X79X8/11 | 38 | 180X205X12/17 | |

| 18 | 63X77X8/11 | 39 | 190X215X12/17 | |

| 19 | 70X84X8/11 | 40 | 200X225X12/17 | |

| 20 | 75X89X8/11 | 41 | 210X235X12/17 | |

| 21 | 80X94X8/11 | |||

| All models can be customized | ||||

Company Profile

ZheJiang Hankai Machinery Equipment Co., Ltd. is a professional manufacture of high quality rubber sealss, its also a foreign trade enterprise that sells worldwide.

It was established in 2004 year, We have advanced producing equipments and precise instruments, and have past the ISO9001 quality assurance standards system.

Our seals have exported to Europe, North America, South America and the Middle East, they all gained great praise and trust from customers at home and abroad. We have more than 10000 kinds of oil seals, which used in engineering machines, mining equipments, oilfied equipments, and automobiles. Our factory always follow advancing forward, pursuing the best, adhere to in-through-quality business policy, and established a complete quality assurance system.

With reliable quality assurance, perfect technical service and the best cost performance, We will adhere to forge ahead, realistic and innovative, united struggle and flexible operating system, , keeping up with market demand, dedicated to all old and new customers with providing quality products, perfect pre-sales and after-sales services, ensure customer satisfaction. Hankai Seal Company wishes to go ahead, develop and prosper with all partners and customers hand in hand!

Packaging & Shipping

FAQ

1.Why choose you?

We are a manufacturer with our factory and have more than 10 years experience for construction machinery oil seal.

2. What is your main products?

Our main products are Cassette seal ,TCN & TCV Type Hydraulic seal ,DKB DKBI GA DLI DKBZ Type Dust seal and concrete mixer seal,

skeleton oil seal and also we offer OEM services.

3. What is your MOQ?

Our MOQ is usually 100 pcs.

4.What is the shipping port?

ZheJiang Port ,HangZhou Port,HangZhou Port.

5.What is your delivery time?

The time of delivery is Two weeks (Working days only) after we receive the deposit.

6, What is your time of making samples?

Usually we will take 15-20 working days to make the samples.

7, How about the samples?

FREE SAMPLES can be send but the freight are charged. After the order is confirmed, we would pay back the express fee.

8.What is your payment terms?

30% T/T in advance,70% in the period of shipment.or Western Union,Paypal.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, CE, ISO9001 |

|---|---|

| Work Temperature: | Normal Temperature |

| Working Method: | Rotary |

| Adjusted Form: | Switching Type |

| Structure: | Rack and Pinion Type |

| Transport Package: | Common |

| Samples: |

US$ 2.43/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

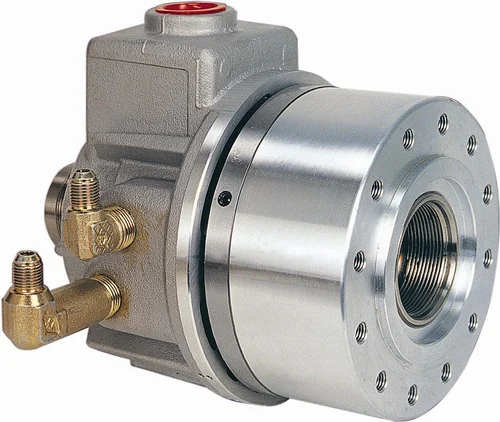

What are the advantages of using rotary cylinders for rotational tasks?

Rotary cylinders offer several advantages when it comes to performing rotational tasks. Here’s a detailed explanation:

1. High Torque Output: Rotary cylinders are capable of delivering high torque output, making them suitable for tasks that require significant rotational force. They can handle heavy loads and provide the necessary power to rotate large components or objects.

2. Precise Control: Rotary cylinders provide precise control over rotational motion. By adjusting the fluid pressure or flow rate, the speed and direction of rotation can be accurately controlled, allowing for precise positioning, indexing, or synchronization with other system components.

3. Compact Size: Rotary cylinders are generally compact in size, making them suitable for applications where space is limited. Their compact design allows for easy integration into machinery and systems without occupying excessive space.

4. Versatility: Rotary cylinders can be used in both hydraulic and pneumatic systems, offering flexibility in system design and integration. They can be seamlessly integrated into existing systems or designed into new systems based on the specific requirements and available resources.

5. Wide Range of Applications: Rotary cylinders find applications in various industries and tasks that involve rotational motion. They are used in indexing tables, robotic arms, material handling equipment, conveyor systems, machine tools, packaging machinery, and more. Their versatility makes them suitable for diverse applications.

6. Reliability and Durability: Rotary cylinders are designed to withstand demanding operating conditions. They are built with robust materials and undergo rigorous testing to ensure reliability and durability. This allows them to perform consistently over extended periods, reducing downtime and maintenance requirements.

7. Cost-Effective: Rotary cylinders can offer cost-effective solutions for rotational tasks. They provide efficient energy conversion, minimizing energy consumption and operating costs. Additionally, their long service life and reliability contribute to cost savings in terms of maintenance and replacement.

It’s important to consider the specific requirements of the application and consult manufacturers’ documentation to ensure the selection and utilization of rotary cylinders that best meet the needs of the rotational tasks.

How do rotary cylinders handle variations in environmental conditions?

Rotary cylinders are designed to handle variations in environmental conditions encountered in different applications. Here’s a detailed explanation:

1. Robust Construction: Rotary cylinders are constructed using durable materials such as high-grade metals, alloys, and seals that can withstand harsh environmental conditions. They are designed to resist factors like vibration, shock, temperature variations, dust, moisture, and exposure to corrosive substances. The robust construction ensures that rotary cylinders can operate reliably and maintain performance integrity in challenging environments.

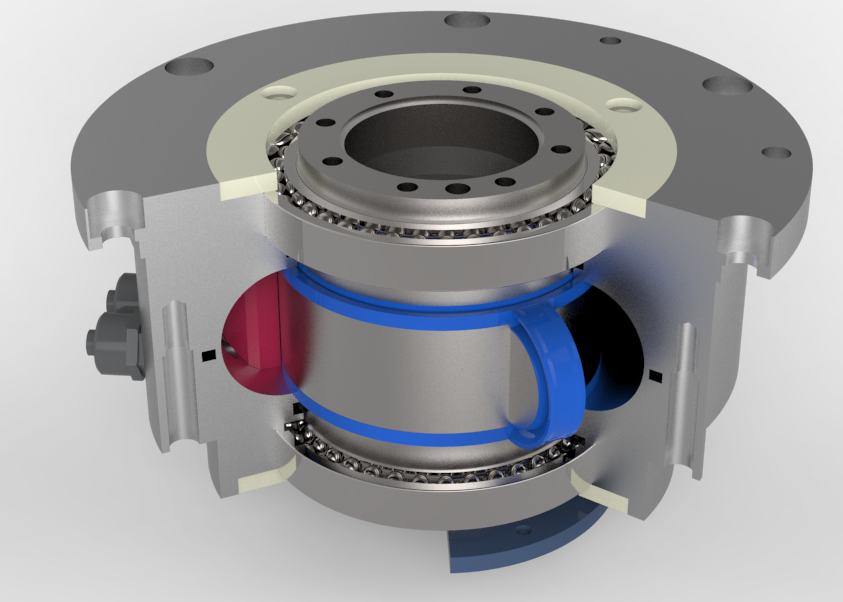

2. Sealing Mechanisms: Rotary cylinders incorporate sealing mechanisms to prevent the ingress of contaminants such as dirt, water, and chemicals. These sealing mechanisms include O-rings, wipers, and lip seals, which create a barrier between the cylinder’s internal components and the external environment. Effective sealing helps protect the cylinder’s internal parts, ensuring smooth operation and preventing damage caused by environmental factors.

3. Lubrication Systems: Proper lubrication is essential for the smooth functioning of rotary cylinders. They are equipped with lubrication systems that deliver lubricants to critical moving parts, reducing friction, wear, and the risk of corrosion. Lubrication systems can be designed to operate under different environmental conditions, ensuring optimal performance and longevity of the cylinder.

4. Temperature Compensation: Rotary cylinders can be designed with temperature compensation features to accommodate variations in operating temperatures. When exposed to high or low temperatures, materials can expand or contract, potentially affecting the cylinder’s performance. Temperature compensation mechanisms, such as thermal expansion compensation or heat dissipation features, help maintain the cylinder’s dimensional stability and performance in different temperature conditions.

5. Protective Coatings: In environments where there is a high risk of corrosion or abrasion, rotary cylinders can be coated with protective layers or treatments. These coatings, such as corrosion-resistant plating, powder coatings, or specialized coatings for specific applications, provide an additional barrier against environmental factors and extend the cylinder’s lifespan.

6. Environmental Testing: Manufacturers subject rotary cylinders to rigorous testing procedures to ensure their performance and reliability under various environmental conditions. These tests may include temperature cycling, humidity exposure, dust and particle ingress testing, vibration testing, and salt spray testing. Environmental testing helps identify potential weaknesses and allows for improvements in design and materials to enhance the cylinder’s ability to handle environmental variations.

7. IP Ratings: In industrial applications, rotary cylinders are often assigned an Ingress Protection (IP) rating. IP ratings indicate the level of protection against solid particles (first digit) and moisture (second digit) that the cylinder can withstand. Higher IP ratings signify greater resistance to environmental factors. Users can select rotary cylinders with appropriate IP ratings based on the specific environmental conditions of their application.

8. Application-Specific Designs: Depending on the industry and application requirements, rotary cylinders can be designed with specific environmental considerations in mind. For example, in marine or offshore applications, cylinders can be corrosion-resistant and designed to withstand saltwater exposure. In dusty environments, additional filtration systems can be incorporated to prevent dust ingress. Customized designs allow rotary cylinders to handle variations in environmental conditions effectively.

By incorporating these features and design considerations, rotary cylinders can effectively handle variations in environmental conditions, ensuring reliable performance and longevity in diverse applications.

Can rotary cylinders be used for both rotary motion and linear motion?

No, rotary cylinders are specifically designed for generating rotary motion and are not typically used for linear motion. Here’s a detailed explanation:

Rotary Motion:

Rotary cylinders, also known as rotary actuators, are primarily used to convert fluid power into rotational motion. They are designed to generate torque and rotate around a central axis. The rotational movement can be in a full 360-degree rotation or limited to a specific angle depending on the application and the design of the cylinder.

Linear Motion:

For linear motion, a different type of actuator, such as linear cylinders or linear actuators, is used. Linear cylinders are specifically designed to generate linear motion by extending or retracting a piston rod in a linear path. These actuators are commonly used in applications where straight-line movement is required, such as pushing, pulling, lifting, or sliding objects.

Differences:

The design and internal mechanism of rotary cylinders are optimized for rotational motion, while linear cylinders are designed to provide linear motion. These two types of actuators have different structures and operating principles to fulfill their respective purposes.

While rotary cylinders cannot directly produce linear motion, they can be part of a system that combines both rotary and linear motion. For example, in some applications, a rotary cylinder can be used to generate rotational motion, which is then converted into linear motion using additional mechanisms such as racks, gears, or linkages.

It’s important to choose the appropriate type of actuator based on the desired motion requirements of the specific application. Manufacturers’ documentation and guidelines should be consulted to determine the most suitable actuator for a particular motion requirement.

editor by CX 2024-01-06