Product Description

Product Description

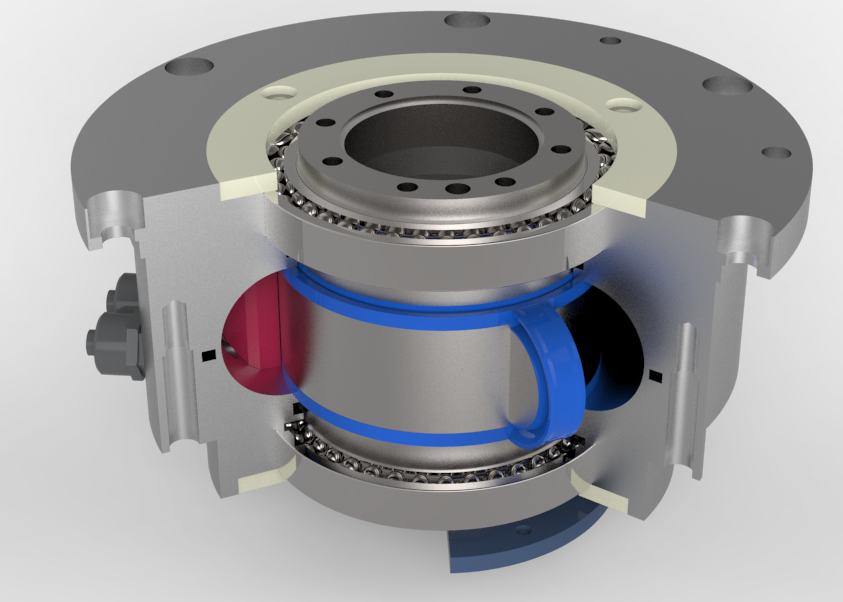

ACK CYLINDER SERIES

Order Code

Pcoduct Features

1. The material of the seal ensures the reliable perfor mance of the cylinder und er various conditions .

2. T he structure of 3 gui de slots has high guiding accuracy .

3. The working modes are unilateral and bilateral (90°).

4. The rotat ion modes are left – CHINAMFG d and right – handed ;90° and 180°.

5. The piston rod is made of special alloy steel , whic h can ensure a longer serv ice life after heat treatmen .

Specification parameters

| Cylinderbore (mm) 25 32 40 50 63 | |

| Mode of movement Working medium The pressure range of use Proof pressure Operating temperature Service speed range Stroke tolerance range Rotation angle tolerance range Buffer form Connection diameter |

Double acting type |

| Air (filtered by more than 40μm) | |

| 0.15~1.0MPa | |

| 1.5MPa | |

| -10~70ºC | |

| 50~200mm/s | |

| +1.0 | |

| ±1.5 | |

| No | |

| M5×0.8 PT1/8 | |

Standard stroke parameters

Product Parameters

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Aluminum |

|---|---|

| Usage: | Automation and Control |

| Structure: | General Cylinder |

| Power: | Pneumatic |

| Standard: | Standard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety considerations are important when working with machinery equipped with rotary cylinders?

Working with machinery equipped with rotary cylinders requires careful attention to safety to prevent accidents and ensure the well-being of operators and bystanders. Here are important safety considerations to keep in mind:

1. Hazard Identification: Identify potential hazards associated with the machinery and its rotary cylinders. This includes understanding the risks posed by rotating parts, high-pressure fluid systems, pinch points, and potential entanglement hazards.

2. Risk Assessment: Conduct a thorough risk assessment to evaluate the potential risks and their severity. Identify measures to mitigate risks and prioritize safety controls accordingly.

3. Safety Guards and Enclosures: Install appropriate safety guards and enclosures to prevent access to hazardous areas, such as rotating components or fluid lines. Ensure that these guards are securely in place and cannot be easily bypassed.

4. Lockout/Tagout Procedures: Develop and enforce lockout/tagout procedures to ensure that machinery equipped with rotary cylinders is properly shut down and de-energized during maintenance or repair activities. This prevents unexpected movement of the cylinders and the potential for injury.

5. Training and Competence: Provide comprehensive training to operators and maintenance personnel on the safe operation of machinery equipped with rotary cylinders. Ensure that they are competent in identifying hazards, understanding safety procedures, and implementing safe work practices.

6. Regular Maintenance and Inspections: Implement a routine maintenance program to keep the machinery and rotary cylinders in good working condition. Regularly inspect the cylinders, fluid lines, fittings, and connections for signs of wear, leaks, or damage. Replace any faulty components promptly.

7. Pressure Relief and Emergency Stop Systems: Install pressure relief valves and emergency stop systems to safely control and halt the operation of machinery in case of emergencies or unexpected events.

8. Warning Signs and Labels: Clearly display warning signs and labels to communicate potential hazards and safety instructions related to the machinery equipped with rotary cylinders. Ensure that operators and other personnel are aware of and understand these warnings.

9. Personal Protective Equipment (PPE): Provide appropriate PPE, such as safety glasses, gloves, and protective clothing, to operators and maintenance personnel. PPE should be used in accordance with relevant safety standards and risk assessments.

10. Continuous Safety Improvement: Foster a culture of continuous safety improvement by encouraging reporting of near misses, conducting regular safety audits, and addressing any identified safety concerns promptly.

It’s essential to comply with local safety regulations and industry standards specific to the machinery and applications using rotary cylinders. Additionally, consult manufacturers’ documentation and guidelines for specific safety considerations related to the rotary cylinders used in the machinery.

Can rotary cylinders be used in manufacturing machinery for indexing?

Yes, rotary cylinders can be used in manufacturing machinery for indexing. Here’s a detailed explanation:

Indexing refers to the precise positioning of components, workpieces, or tools at specific intervals or angles in manufacturing processes. Rotary cylinders are well-suited for indexing applications due to their ability to provide controlled and precise rotational motion. Here’s how they are used:

1. Rotary Motion Generation: Rotary cylinders convert fluid power, either hydraulic or pneumatic, into rotary motion. By controlling the flow of fluid into and out of the cylinder, the rotary motion can be accurately regulated. This controlled rotation is essential for indexing applications where precise angular positioning is required.

2. Angular Displacement: Rotary cylinders enable angular displacement with high accuracy. They can rotate a component or workpiece to a specific angle or index it at precise intervals. This capability is crucial in manufacturing processes that involve operations such as cutting, drilling, assembly, or inspection at specific angular positions.

3. Positioning Accuracy: Rotary cylinders offer excellent positioning accuracy, allowing for precise indexing. By combining precise control of fluid flow with position feedback devices such as rotary encoders or potentiometers, the cylinder can accurately reach and maintain specific angular positions. This level of positioning accuracy ensures that indexing operations are performed with high precision and repeatability.

4. Speed and Acceleration Control: Rotary cylinders provide control over the rotational speed and acceleration, enabling smooth and gradual indexing movements. By adjusting the fluid flow rate or pressure, the rotational velocity and acceleration can be precisely controlled. This feature is particularly beneficial in indexing applications that require gradual start-up or deceleration to prevent abrupt movements or damage to the workpiece.

5. Compact and Lightweight Design: Rotary cylinders are often designed to be compact and lightweight, making them suitable for integration into manufacturing machinery. Their compact size allows for efficient use of space, while their lightweight nature reduces rotational inertia and enables faster response times. These design characteristics contribute to the overall efficiency and performance of indexing operations.

6. Integration with Control Systems: Rotary cylinders can be seamlessly integrated into control systems such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems. This integration enables precise coordination and synchronization of the rotary motion with other machine operations, ensuring accurate indexing within the overall manufacturing process.

7. Customization: Manufacturers offer a wide range of rotary cylinder models with different sizes, load capacities, and performance characteristics. This allows users to select the most suitable cylinder for their specific indexing application. Customization options further enhance the ability to tailor the cylinder’s performance to meet specific indexing requirements.

8. Compatibility with Machine Tools: Rotary cylinders can be integrated with machine tools used in manufacturing processes. They can be coupled with indexing tables, rotary stages, or tool turrets to achieve precise angular positioning and indexing of workpieces or tools. This integration enhances the versatility and functionality of the manufacturing machinery.

By incorporating these features, rotary cylinders contribute to efficient and accurate indexing in manufacturing machinery, enabling precise positioning and synchronization of components or tools in various industrial processes.

How does a rotary cylinder differ from other types of hydraulic cylinders?

A rotary cylinder differs from other types of hydraulic cylinders in several ways. Here’s a detailed explanation:

Principle of Operation:

A rotary cylinder is designed to convert fluid power into rotational motion, while other types of hydraulic cylinders primarily provide linear motion. While standard hydraulic cylinders extend and retract in a straight line, a rotary cylinder generates rotary or swinging motion.

Mechanism:

Rotary cylinders utilize different mechanisms to produce rotary motion. They may employ rack-and-pinion mechanisms, vane mechanisms, or gear mechanisms, depending on the specific design. In contrast, other types of hydraulic cylinders typically use a piston and cylinder arrangement to generate linear motion.

Direction of Motion:

Rotary cylinders produce rotational motion around a fixed axis or pivot point. The direction of rotation can be clockwise or counterclockwise, depending on the design and configuration of the cylinder. In contrast, other hydraulic cylinders provide linear motion in a straight line, either extending or retracting along the axis of the cylinder.

Applications:

Rotary cylinders are commonly used in applications where rotational movement is required, such as rotary indexing tables, robotic arms, and conveyor systems. They are suitable for tasks that involve swinging, rotating, or indexing motions. On the other hand, other types of hydraulic cylinders are used in applications that primarily require linear motion, such as lifting, pushing, or pulling.

Advantages and Disadvantages:

Rotary cylinders offer certain advantages over other types of hydraulic cylinders. They provide compact and efficient means of generating rotary motion, allowing for versatile applications. Rotary cylinders can deliver high torque output and precise control over rotational motion. However, one potential disadvantage is that they may have a more complex design and require additional components compared to standard hydraulic cylinders.

Fluid Medium:

Rotary cylinders can be powered by either hydraulic fluid or compressed air, depending on the specific design and application. Other types of hydraulic cylinders also utilize hydraulic fluid as the power medium. The choice of fluid medium depends on factors such as the desired force and speed, environmental considerations, and system requirements.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the selection, installation, and operation of rotary cylinders and other types of hydraulic cylinders for different applications.

editor by CX 2023-12-28