Product Description

50 ton hydraulic cylinder 393 (100mm) stroke jack

1.Describe:

Hydraulic cylinder can bear partial loading is 5% of rated pressure. High pressure alloy cylinder is very durable, especially in the larger project, it is easily to be operated and control. It can be used for lifting heavy machine, bridge project, hydraulic engineering, harbour construction and other equipment. It has large output, light weight, remote control and other advantages, it can match with our high pressure oil pump, it can reach jack, push, pull and extrusion and kinds of working.

2. Features

1. Integral stop ring provides piston blow-out protection

2. Double-acting for positive retraction

3. Baked enamel outside finish and plated pistons provide superior corrosion resistance

4. Safety valve in retract side of cylinder helps to prevent damage in case of accidental over-pressurization

5. Interchangeable, hardened grooved saddles are standard

6. Plunger wiper reduces contamination, extending cylinder life

| Model | Tonnage T | Stroke mm | Closed height mm | Extend height mm | Outer diameter of oil cylinder mm | Dimension of plunger mm | Dimension of oil pump mm | Weight kg | Pressure |

| STQ50-100 | 50 | 100 | 225 | 325 | 127 | 70 | 100 | 35 | 63MPA |

| STQ50-160 | 160 | 285 | 445 | 39 | |||||

| STQ50-200 | 200 | 325 | 525 | 46 | |||||

| STQ50-300 | 300 | 425 | 725 | 48 | |||||

| STQ50-500 | 500 | 625 | 1125 | 63 | |||||

| STQ100-100 | 100 | 100 | 250 | 350 | 180 | 100 | 140 | 58 | |

| STQ100-160 | 160 | 310 | 470 | 63 | |||||

| STQ100-200 | 200 | 350 | 550 | 78 | |||||

| STQ100-300 | 300 | 450 | 750 | 96 | |||||

| STQ100-500 | 500 | 650 | 1150 | 130 | |||||

| STQ150-100 | 150 | 100 | 260 | 360 | 219 | 125 | 180 | 58 | |

| STQ150-160 | 160 | 320 | 480 | 69 | |||||

| STQ150-200 | 200 | 360 | 560 | 86 | |||||

| STQ150-300 | 300 | 460 | 760 | 103 | |||||

| STQ150-500 | 500 | 660 | 1160 | 255 | |||||

| STQ200-100 | 200 | 100 | 285 | 385 | 240 | 150 | 200 | 96 | |

| STQ200-160 | 160 | 345 | 505 | 103 | |||||

| STQ200-200 | 200 | 385 | 585 | 116 | |||||

| STQ200-300 | 300 | 485 | 785 | 161 | |||||

| STQ200-500 | 500 | 685 | 1185 | 221 | |||||

| STQ320-100 | 320 | 100 | 310 | 410 | 330 | 180 | 250 | 196 | |

| STQ320-160 | 160 | 370 | 530 | 240 | |||||

| STQ320-200 | 200 | 410 | 610 | 258 | |||||

| STQ320-300 | 300 | 510 | 810 | 311 | |||||

| STQ320-500 | 500 | 710 | 1210 | 456 | |||||

| STQ400-100 | 400 | 100 | 355 | 455 | 380 | 200 | 290 | 198 | |

| STQ400-160 | 160 | 415 | 575 | 231 | |||||

| STQ400-200 | 200 | 460 | 660 | 264 | |||||

| STQ400-300 | 300 | 555 | 855 | 367 | |||||

| STQ400-500 | 500 | 755 | 1255 | 456 | |||||

| STQ500-100 | 500 | 100 | 360 | 460 | 430 | 200 | 320 | 323 | |

| STQ500-160 | 160 | 420 | 580 | 330 | |||||

| STQ500-200 | 200 | 460 | 660 | 420 | |||||

| STQ500-300 | 300 | 560 | 860 | 581 | |||||

| STQ500-500 | 500 | 760 | 1260 | 599 | |||||

| STQ630-100 | 630 | 100 | 417 | 517 | 500 | 250 | 360 | 560 | |

| STQ630-160 | 160 | 477 | 637 | 633 | |||||

| STQ630-200 | 200 | 517 | 717 | 696 | |||||

| STQ630-300 | 300 | 617 | 917 | 898 | |||||

| STQ630-500 | 500 | 817 | 1317 | 1250 | |||||

| STQ800-100 | 800 | 100 | 488 | 588 | 560 | 300 | 400 | 896 | |

| STQ800-200 | 200 | 598 | 798 | 1040 | |||||

| STQ800-300 | 300 | 698 | 998 | 1380 | |||||

| STQ800-500 | 500 | 898 | 1398 | 1520 | |||||

| STQ1000-100 | 1000 | 100 | 530 | 630 | 600 | 320 | 450 | 1286 | |

| STQ1000-200 | 200 | 630 | 830 | 1332 | |||||

| STQ1000-300 | 300 | 760 | 1060 | 1663 |

If the model you are looking for is not available, please contact us! We will customize it according to your needs.

3. Application:

Our hydraulic jacks have been widely used for industrial field, such as steel plant, cement industry, chemical and refinery, bridge, railway, highway, hydropower station, ship repair, building, construction and maintenance.

4.Company information:

HangZhou Lead Equipment Co., Ltd. Have been in hydraulic tools industry since 2009.

Our main products as follow:

Single acting hydraulic jack/cylinder/ram (10-100 tons)

Single acting hollow hydraulic jack/cylinder/ram (12-100 tons)

Double acting hydraulic jack/cylinder/ram (50-2000 tons)

Double acting hollow hydraulic jack/cylinder/ram (50-2000 tons)

Single acting hydraulic jack/cylinder/ram with lock nut (55-200 tons)

Thin type single acting hydraulic jack/cylinder/ram (10-200 tons)

Ultrathin hydraulic jack/cylinder/ram (10-200 tons)

Flange type hydraulic jack/cylinder/ram (10-630 tons)

Synchronous hydraulic jack (10-1000 tons)

Hydraulic accessories: high pressure oil hose, couplers, seal kits, mainfold, etc.

All the tonnage, stroke, height can be customized according to client’s requirements, supply the best quality and serve. Our warranty is 2 years.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, SGS |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Rotary |

| Adjusted Form: | Switching Type |

| Customization: |

Available

|

|

|---|

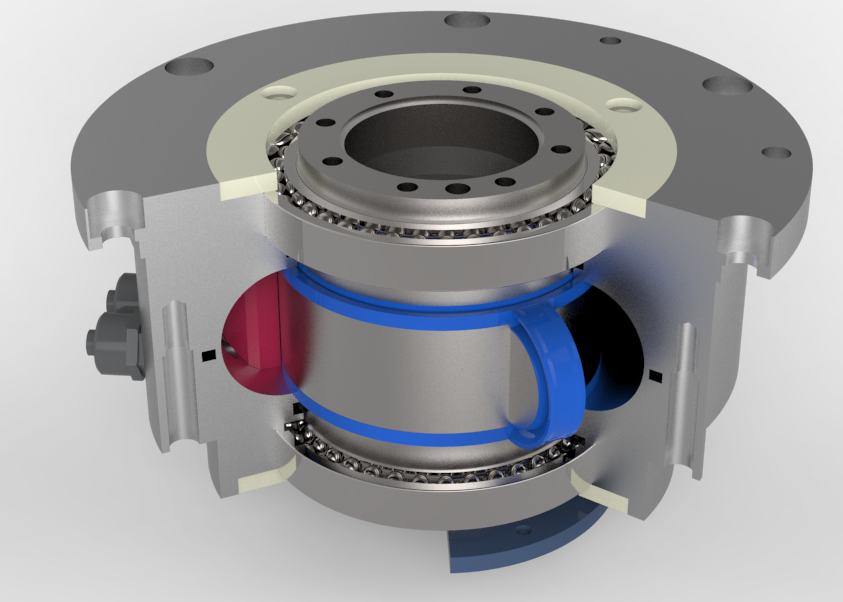

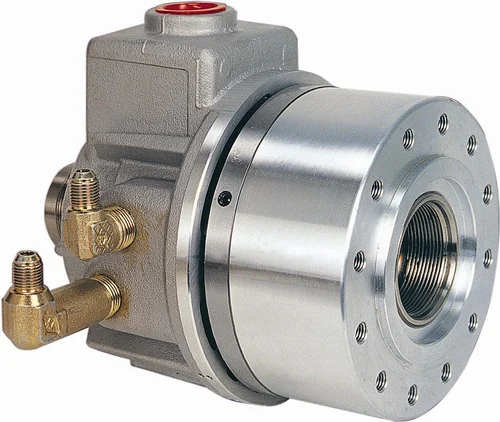

Can rotary cylinders be customized for specific machinery and equipment?

Yes, rotary cylinders can be customized to meet the specific requirements of different machinery and equipment. Here’s a detailed explanation:

1. Mounting Options: Rotary cylinders can be customized with various mounting options to ensure seamless integration with specific machinery and equipment. Different mounting styles, such as flange mounts, foot mounts, or clevis mounts, can be provided to accommodate the mounting needs of the application.

2. Shaft Configurations: Rotary cylinders can be customized with different shaft configurations to suit specific machinery and equipment designs. The shaft can be extended or modified to match the required dimensions, keyways, or connections necessary for the intended application.

3. Stroke Length: The stroke length of rotary cylinders can be customized to meet the specific range of rotational motion required by the machinery or equipment. By adjusting the stroke length, the rotary cylinder can be tailored to provide the desired angular movement.

4. Sealing Options: Rotary cylinders can be customized with various sealing options to ensure compatibility with different operating environments. Different types of seals, such as nitrile, Viton®, or polyurethane seals, can be used based on factors like temperature, pressure, and the presence of corrosive or abrasive substances.

5. Special Features: Depending on the application requirements, rotary cylinders can be customized with special features. This may include the integration of position sensors, encoders, or limit switches to provide feedback and enhance control. Additionally, custom ports, fittings, or connections can be added to facilitate the integration of the cylinder into the specific machinery or equipment.

6. Material Selection: The materials used in the construction of rotary cylinders can be customized based on factors such as the operating environment, load requirements, or chemical compatibility. Custom material selection ensures the cylinder’s durability and performance in the specific machinery and equipment.

7. Performance Parameters: Rotary cylinders can be customized to meet specific performance parameters, such as torque output, rotational speed, or response time. By adjusting the internal design and components, the cylinder’s performance can be optimized for the particular machinery or equipment.

It’s important to collaborate with manufacturers or suppliers who specialize in customizing rotary cylinders for specific machinery and equipment. They can provide guidance and expertise in tailoring the cylinder to meet the precise requirements of the application.

Can rotary cylinders be used in manufacturing machinery for indexing?

Yes, rotary cylinders can be used in manufacturing machinery for indexing. Here’s a detailed explanation:

Indexing refers to the precise positioning of components, workpieces, or tools at specific intervals or angles in manufacturing processes. Rotary cylinders are well-suited for indexing applications due to their ability to provide controlled and precise rotational motion. Here’s how they are used:

1. Rotary Motion Generation: Rotary cylinders convert fluid power, either hydraulic or pneumatic, into rotary motion. By controlling the flow of fluid into and out of the cylinder, the rotary motion can be accurately regulated. This controlled rotation is essential for indexing applications where precise angular positioning is required.

2. Angular Displacement: Rotary cylinders enable angular displacement with high accuracy. They can rotate a component or workpiece to a specific angle or index it at precise intervals. This capability is crucial in manufacturing processes that involve operations such as cutting, drilling, assembly, or inspection at specific angular positions.

3. Positioning Accuracy: Rotary cylinders offer excellent positioning accuracy, allowing for precise indexing. By combining precise control of fluid flow with position feedback devices such as rotary encoders or potentiometers, the cylinder can accurately reach and maintain specific angular positions. This level of positioning accuracy ensures that indexing operations are performed with high precision and repeatability.

4. Speed and Acceleration Control: Rotary cylinders provide control over the rotational speed and acceleration, enabling smooth and gradual indexing movements. By adjusting the fluid flow rate or pressure, the rotational velocity and acceleration can be precisely controlled. This feature is particularly beneficial in indexing applications that require gradual start-up or deceleration to prevent abrupt movements or damage to the workpiece.

5. Compact and Lightweight Design: Rotary cylinders are often designed to be compact and lightweight, making them suitable for integration into manufacturing machinery. Their compact size allows for efficient use of space, while their lightweight nature reduces rotational inertia and enables faster response times. These design characteristics contribute to the overall efficiency and performance of indexing operations.

6. Integration with Control Systems: Rotary cylinders can be seamlessly integrated into control systems such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems. This integration enables precise coordination and synchronization of the rotary motion with other machine operations, ensuring accurate indexing within the overall manufacturing process.

7. Customization: Manufacturers offer a wide range of rotary cylinder models with different sizes, load capacities, and performance characteristics. This allows users to select the most suitable cylinder for their specific indexing application. Customization options further enhance the ability to tailor the cylinder’s performance to meet specific indexing requirements.

8. Compatibility with Machine Tools: Rotary cylinders can be integrated with machine tools used in manufacturing processes. They can be coupled with indexing tables, rotary stages, or tool turrets to achieve precise angular positioning and indexing of workpieces or tools. This integration enhances the versatility and functionality of the manufacturing machinery.

By incorporating these features, rotary cylinders contribute to efficient and accurate indexing in manufacturing machinery, enabling precise positioning and synchronization of components or tools in various industrial processes.

Can rotary cylinders be used for both rotary motion and linear motion?

No, rotary cylinders are specifically designed for generating rotary motion and are not typically used for linear motion. Here’s a detailed explanation:

Rotary Motion:

Rotary cylinders, also known as rotary actuators, are primarily used to convert fluid power into rotational motion. They are designed to generate torque and rotate around a central axis. The rotational movement can be in a full 360-degree rotation or limited to a specific angle depending on the application and the design of the cylinder.

Linear Motion:

For linear motion, a different type of actuator, such as linear cylinders or linear actuators, is used. Linear cylinders are specifically designed to generate linear motion by extending or retracting a piston rod in a linear path. These actuators are commonly used in applications where straight-line movement is required, such as pushing, pulling, lifting, or sliding objects.

Differences:

The design and internal mechanism of rotary cylinders are optimized for rotational motion, while linear cylinders are designed to provide linear motion. These two types of actuators have different structures and operating principles to fulfill their respective purposes.

While rotary cylinders cannot directly produce linear motion, they can be part of a system that combines both rotary and linear motion. For example, in some applications, a rotary cylinder can be used to generate rotational motion, which is then converted into linear motion using additional mechanisms such as racks, gears, or linkages.

It’s important to choose the appropriate type of actuator based on the desired motion requirements of the specific application. Manufacturers’ documentation and guidelines should be consulted to determine the most suitable actuator for a particular motion requirement.

editor by CX 2023-12-25