Product Description

Product Description

| CW-A-10T Overall Dimension | ||||

| Total Stroke | Power Stroke | L | L1 | L2 |

| 50 | 5 | 305 | 480 | 393 |

| 100 | 5 | 355 | 580 | 443 |

| 150 | 5 | 405 | 680 | 493 |

| 200 | 5 | 455 | 780 | 543 |

| 50 | 10 | 305 | 480 | 457 |

| 100 | 10 | 355 | 580 | 507 |

| 150 | 10 | 405 | 680 | 557 |

| 200 | 10 | 455 | 780 | 607 |

| 50 | 15 | 305 | 480 | 521 |

| 100 | 15 | 355 | 580 | 571 |

| 150 | 15 | 405 | 680 | 621 |

| 200 | 15 | 455 | 780 | 671 |

| 50 | 20 | 305 | 530 | 635 |

| 100 | 20 | 355 | 580 | 635 |

| 150 | 20 | 405 | 680 | 685 |

| 200 | 20 | 455 | 780 | 735 |

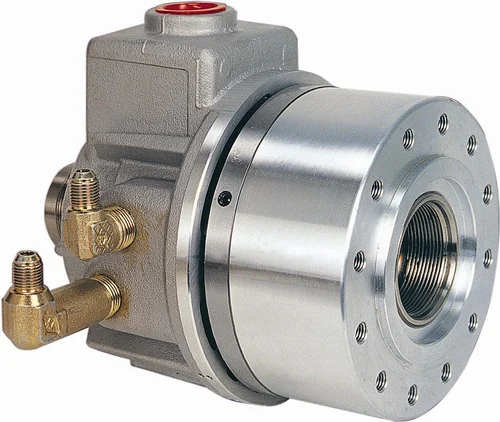

Specification

| Action type | Double action |

| Action pressure | Clean compressed air of 3-7kg/cm² |

| Action-wear hydraulicoil | Anti-wear hydraulic oil of VG 68# |

| Operation temperature | 0-55ºC |

| Operating speed | 10-400mm/s |

| Anti-pressure of oil tank | 300kg/cm² |

| Anti-pressure of pneumatic cylinder | 12kg/cm² |

| Prepress stroke tolerance | +1.00mm 0.00mm |

| Power stroke tolerance | +0.20mm 0.00mm |

| Operation frequency | 10-50 times (related to the specific pre-pressure and booster stroke) |

| High pressure Boosting force | 1-80T(the actual output tonnage according to the customer demand) |

Product Features

Working Principle

pneumatic cylinder is combined the oil pressure cylinder and booster together for taking pure gas press as the power source. It makes use of the different size of booster, the crosssection area compression ratio and Pascal energy conservation principle. Because of constant pressure, when the compression area change from small to large, the press would vary with the size, so as to raise the gas pressure to tens. Taking the prepress standard hydro pneumatic cylinder as an example: When the work gas pressed on the hydraulic oil (or working piston) surface, hydraulic oil would flow to the approach stroke cavity because of the air pressure, then the hydraulic oil would promote the workpiece to move rapidly. When the workpiece is meet the resistance larger than the gas pressure, it stops moving. At this point, the booster cavity start moving because of the signal (or pneumatic signal), then achieve the purpose of moding products!

Features:

1.Fast speed: The action speed is faster than the hydraulic drive and it is more stability than pneumatic drive;

2.High output: It can reach the highest output of oil hydraulic machine under same conditions, which can not be achieved by the pure pneumatic machine;

3.Low price: The price is lower than the oil pressure system;

4.Easy to maintain: The simple structure is easier to maintain than the oil pressure system;

5.Low energy consumption: When continue to boost or stop moving, it does not need the motor to keep working as the hydraulic system,

then the energy can be saved. And it is convenient to take the power source, so the actual energy

consumption is equivalent to 10%-30% of hydraulic power system;

6.No leakage: Energy conversion is easy with zero leakage, so not worry about the environmental pollution;

7.No harm to the die: In order to meet the technology needs, stamping pressure and the work stroke can keep within the provided area without adjustable levels;

8.Soft landing: Soft-stamping technology reduce the noise to protect the die;

9.Fault less: No temperature rising problems unlike the hydraulic system;

10.Small space: Space area can be less than 50% compare with normal air cylinder and hydraulic station;

Factory Display

Packaging

Company Introduction

CHINAMFG Machinery Equipment Co.,Ltd supply a wide range of high quality punching machine, hydraulic press machine, automatic riveting machine,eyelet punching machine, hydro pneumatic press machine,air liquid booster pump, pneumatic hydraulic components and other automation equipment. Committed to the complete solution from design to manufacturing to meet customer demand.

Our company has a professional technical team, nearly 30 years of experience in this area. Our products are widely used in aerospace, new energy, automobile and boating, petrochemical, mold, clothing and other fields.Our products are exported to Europe, South America, North America, southeast Asia, South Africa and other places.

CHINAMFG has always adhered to the principle of “Integrity, Professionalism, Technology and Innovation”,to provide high quality solutions to the customers and all aspects of service, strive to make the world love made in China.Corporate Philosophy: Integrity as Root, Customer-Based Culture; Science and Technology Innovation. Sharina and Co-Win.

Certifications

Professional technical team, nearly 30 years of industry experience;

Lean production management mode combines market demand, product research and development, production and manufacturing.pre-sales quality and after-sales service;

Advanced equipment, mature technology, with a number of independent intellectual vproperty rights;

Complete quality control, assured quality, from raw material procurement,production process control, to finished product inspection, packaging, full field monitoring traceability, to ensure that every product qualified;

Has 3 specialized processing and manufacturing factories, sufficient inventory, short delivery time;

Support customized, design according to customer requirements to meet the diversified demand of customers;

Perfect after-sales service system and after-sales quality tracking system;

Professional sales system, rich experience in export related operation process.

| Material: | Steel |

|---|---|

| Usage: | Automation and Control |

| Structure: | Piston Cylinder |

| Power: | Pneumatic |

| Standard: | Nonstandard |

| Pressure Direction: | Double-acting Cylinder |

| Customization: |

Available

|

|

|---|

How do rotary cylinders contribute to precise rotational control?

Rotary cylinders play a crucial role in achieving precise rotational control in various applications. Here’s a detailed explanation:

1. Actuation Methods: Rotary cylinders utilize hydraulic or pneumatic actuation methods to generate rotational motion. These actuation methods offer precise control over the application of force, allowing for accurate and controlled rotation.

2. Control Valves: Control valves are used to regulate the fluid flow into and out of the rotary cylinder. By adjusting the valve settings, the rotational speed and direction can be precisely controlled, enabling precise rotational control.

3. Feedback Systems: Some rotary cylinders incorporate feedback systems, such as position sensors or encoders, to provide real-time information about the cylinder’s rotational position. This feedback enables precise control over the rotational movement, allowing for accurate positioning and synchronization with other system components.

4. Stroke Adjustment: Rotary cylinders often have adjustable stroke lengths, which allow for precise control over the range of rotational movement. By adjusting the stroke, the rotational angle can be precisely controlled, enabling precise rotational control for specific applications.

5. Positioning Guides: Rotary cylinders may feature positioning guides, such as grooves or slots, that help guide and stabilize the rotational movement. These guides ensure precise alignment and minimize deviations or wobbling during operation, contributing to precise rotational control.

6. Precision Manufacturing: Rotary cylinders are manufactured with high precision to ensure smooth and accurate rotation. The use of high-quality materials, precision machining, and tight tolerances contribute to precise rotational control, minimizing unwanted variations or errors.

7. Integration with Control Systems: Rotary cylinders can be seamlessly integrated with control systems, allowing for precise control over the rotational motion. They can be programmed and synchronized with other system components, such as sensors, actuators, and PLCs, to achieve precise rotational control in complex automation processes.

These factors combined contribute to the precise rotational control achieved through the utilization of rotary cylinders. It’s important to consult manufacturers’ documentation and guidelines for specific information on the capabilities and limitations of rotary cylinders in achieving precise rotational control.

Can rotary cylinders be applied in both mobile and stationary machinery?

Yes, rotary cylinders can be applied in both mobile and stationary machinery. Here’s a detailed explanation:

1. Mobile Machinery: Rotary cylinders find extensive use in mobile machinery, such as construction equipment, agricultural machinery, material handling equipment, and transportation vehicles. In these applications, rotary cylinders enable controlled rotational motion for various functions, including steering, lifting, tilting, opening and closing attachments, and actuating hydraulic brakes. The compact design and versatility of rotary cylinders make them well-suited for mobile machinery, where space and weight considerations are crucial.

2. Stationary Machinery: Rotary cylinders are also widely utilized in stationary machinery across various industries. They play a crucial role in applications such as industrial automation, manufacturing processes, packaging equipment, robotics, and machine tools. In stationary machinery, rotary cylinders provide controlled rotation for tasks such as part positioning, indexing, clamping, cutting, and material handling. The precise and repeatable rotational motion offered by rotary cylinders contributes to the overall efficiency and productivity of stationary machinery.

3. Versatile Mounting Options: Rotary cylinders come with versatile mounting options, allowing them to be easily integrated into different types of machinery, whether mobile or stationary. They can be mounted in various orientations and configurations to suit specific application requirements. This flexibility in mounting ensures that rotary cylinders can be effectively applied in diverse machinery designs.

4. Customization: Manufacturers offer a wide range of rotary cylinder models with different sizes, load capacities, and performance characteristics. This allows users to select the most suitable cylinder for their specific mobile or stationary machinery application. Additionally, rotary cylinders can be customized to meet specific requirements, such as stroke length, rotational speed, and mounting interfaces, further enhancing their applicability in both mobile and stationary contexts.

5. Environmental Considerations: Rotary cylinders are designed and engineered to withstand various environmental conditions encountered in both mobile and stationary machinery. They are constructed using durable materials that can withstand factors such as vibration, shock, temperature variations, and exposure to dust, moisture, or corrosive substances. This ensures reliable performance and longevity, regardless of whether the machinery is mobile or stationary.

6. Integration with Control Systems: Rotary cylinders can be seamlessly integrated into control systems, such as hydraulic or pneumatic control circuits, electronic control units (ECUs), or programmable logic controllers (PLCs). This integration allows for precise control and coordination of the rotary motion with other machine functions, enabling efficient operation and automation in both mobile and stationary machinery.

Overall, the adaptability, versatility, and performance characteristics of rotary cylinders make them suitable for application in a wide range of machinery, whether it is mobile or stationary, contributing to enhanced functionality and efficiency in various industries.

Can rotary cylinders be used for both rotary motion and linear motion?

No, rotary cylinders are specifically designed for generating rotary motion and are not typically used for linear motion. Here’s a detailed explanation:

Rotary Motion:

Rotary cylinders, also known as rotary actuators, are primarily used to convert fluid power into rotational motion. They are designed to generate torque and rotate around a central axis. The rotational movement can be in a full 360-degree rotation or limited to a specific angle depending on the application and the design of the cylinder.

Linear Motion:

For linear motion, a different type of actuator, such as linear cylinders or linear actuators, is used. Linear cylinders are specifically designed to generate linear motion by extending or retracting a piston rod in a linear path. These actuators are commonly used in applications where straight-line movement is required, such as pushing, pulling, lifting, or sliding objects.

Differences:

The design and internal mechanism of rotary cylinders are optimized for rotational motion, while linear cylinders are designed to provide linear motion. These two types of actuators have different structures and operating principles to fulfill their respective purposes.

While rotary cylinders cannot directly produce linear motion, they can be part of a system that combines both rotary and linear motion. For example, in some applications, a rotary cylinder can be used to generate rotational motion, which is then converted into linear motion using additional mechanisms such as racks, gears, or linkages.

It’s important to choose the appropriate type of actuator based on the desired motion requirements of the specific application. Manufacturers’ documentation and guidelines should be consulted to determine the most suitable actuator for a particular motion requirement.

editor by CX 2023-11-27