Product Description

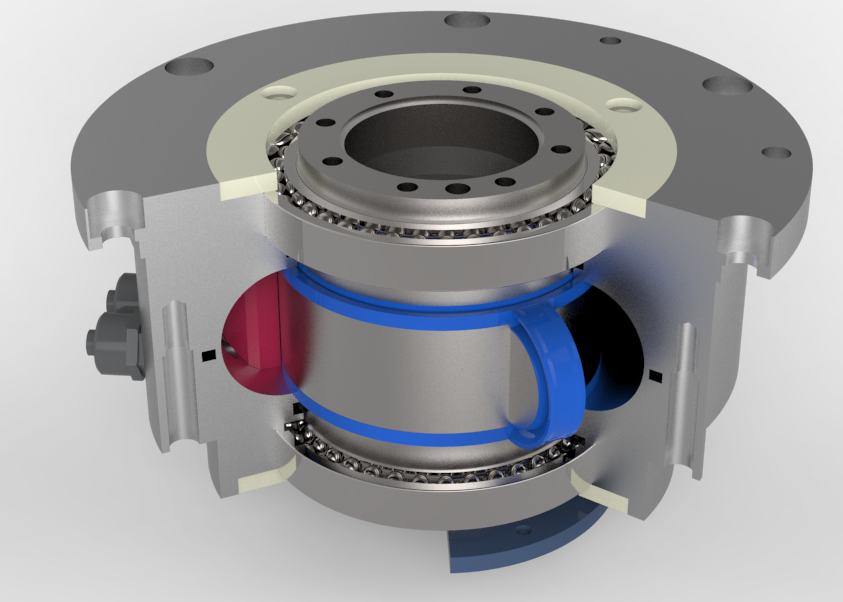

SRC25 rotary clamp cylinder CHINAMFG Clamping Rotary Cylinder

Product Description

1).Bore:25mm, 32mm, 40mm, 50mm, 63mm

2).Small size and light weight.

3).Long service of life, easy to control and maintain.

4).Interchange with SMC

Applicable for positioning, transportation, quantitative filling, right and left displacement, flow control, etc. capable of accuracy and speedy purpose.

Corresponding auto switch selection

Our company can also provide the following cylinders:

1. Standard cylinder: SC, SU, SI, SE, DNC……

2. Mini cylinder: MA, MAL, CJ2, CM2, CJP, MI, MF…

3. Double shaft cylinder: TN, CXS……

4. Free installation of cylinders: CU, CDU……

5. Slide cylinder: MXS, MXQ, MXH, MXP, STM……

6. Three-axis cylinder: MGPM, MGJ, MGG, MGC, TCM…

7. Rotating cylinder: MSQB, CRA1, CRQ2B……

8. Thin cylinder: SDA, CQ2, CQM……

9. Corner cylinder: ACK, SRC, MK…

10. Rodless cylinder: CY1, CY3, RMT, RMS, MY1……

11. Finger cylinder: MHZ2, MHZL2, MHC2, MHL2, MHY2, MHS, MHF2, MHT2, MHCA…

12. Other non-standard customized cylinders, customized according to drawings

Packaging & Shipping

Company Profile

Hangyuan Technology is a professional research and development, design,manufacture and sales of precision filtration, precision pressure reducing valve, solenoid control valve, pulse solenoid valve, pneumatic control valve, various electric cylinders and high and low pressure joints, high-quality pipelines and other pneumatic components products manufacturer. And persistently insist on service and quality first, and quick delivery response.

In recent years, we have continuously invested in research and development and quality improvement, and have cooperated with domestic and foreign high-quality material suppliers, seal and grease and other parts suppliers, and surface treatment suppliers to provide diversified and customized products.

We are willing to provide automation The industry will do its best to improve production efficiency and effectively reduce costs, and become a good partner and high-quality supplier for our customers; we look CHINAMFG to the support and advice of advanced benefits from all industries.

FAQ

Q1:What is your quality assurance?

A:We will inspect 1 by 1 before delivery.If the product is damaged in transit or has quality problems, you can choose to refund or resend the product, and the freight will be borne by us.

Q2:What is your terms of payment?

A: TT ,We’ll show you the photos of the products and packages before you pay the balance.

B: Paypal payment, Western Union,Bank transfer,Made-in-china Trade Assurance order also available.

Q3: How about the lead time?

A: Normally it will take 3-7 days for our routine products.

Q4:What is your sample policy?

A: Some free samples can be offered if you contact us.

Q5:How about the warranty?

A: All of our products will be guaranteed 1 year warranty.

—- HYTIC . Other Hot products ——–

1. EXECUTING COMPONENT

2.CONTROL COMPONENT

3.AIR SOURCE TREATMENT

| Material: | Aluminum Alloy |

|---|---|

| Usage: | Print, Semiconductor, Automation and Control, Robot |

| Structure: | Piston Cylinder |

| Power: | Pneumatic |

| Standard: | Standard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What are the advantages of using rotary cylinders for rotational tasks?

Rotary cylinders offer several advantages when it comes to performing rotational tasks. Here’s a detailed explanation:

1. High Torque Output: Rotary cylinders are capable of delivering high torque output, making them suitable for tasks that require significant rotational force. They can handle heavy loads and provide the necessary power to rotate large components or objects.

2. Precise Control: Rotary cylinders provide precise control over rotational motion. By adjusting the fluid pressure or flow rate, the speed and direction of rotation can be accurately controlled, allowing for precise positioning, indexing, or synchronization with other system components.

3. Compact Size: Rotary cylinders are generally compact in size, making them suitable for applications where space is limited. Their compact design allows for easy integration into machinery and systems without occupying excessive space.

4. Versatility: Rotary cylinders can be used in both hydraulic and pneumatic systems, offering flexibility in system design and integration. They can be seamlessly integrated into existing systems or designed into new systems based on the specific requirements and available resources.

5. Wide Range of Applications: Rotary cylinders find applications in various industries and tasks that involve rotational motion. They are used in indexing tables, robotic arms, material handling equipment, conveyor systems, machine tools, packaging machinery, and more. Their versatility makes them suitable for diverse applications.

6. Reliability and Durability: Rotary cylinders are designed to withstand demanding operating conditions. They are built with robust materials and undergo rigorous testing to ensure reliability and durability. This allows them to perform consistently over extended periods, reducing downtime and maintenance requirements.

7. Cost-Effective: Rotary cylinders can offer cost-effective solutions for rotational tasks. They provide efficient energy conversion, minimizing energy consumption and operating costs. Additionally, their long service life and reliability contribute to cost savings in terms of maintenance and replacement.

It’s important to consider the specific requirements of the application and consult manufacturers’ documentation to ensure the selection and utilization of rotary cylinders that best meet the needs of the rotational tasks.

Can rotary cylinders be repaired or maintained when needed?

Yes, rotary cylinders can be repaired and maintained when needed to ensure their optimal performance and longevity. Here’s a detailed explanation:

1. Routine Maintenance: Regular maintenance is essential to keep rotary cylinders in good working condition. This includes tasks such as cleaning, lubrication, and inspection of components. Routine maintenance helps prevent issues and prolongs the cylinder’s lifespan.

2. Seal Replacement: Seals are critical components of rotary cylinders and may require periodic replacement due to wear or damage. Replacing seals at recommended intervals helps maintain proper sealing and prevent fluid leaks.

3. Component Replacement: In case of component failure or damage, individual components of the rotary cylinder can be replaced. This may include piston rods, seals, bearings, or other internal parts. Replacement parts should be sourced from reputable manufacturers or suppliers to ensure compatibility and quality.

4. Fluid Flush and Filter Replacement: Over time, hydraulic or pneumatic fluid used in rotary cylinders may become contaminated with particles or degrade in quality. Performing fluid flushes and replacing filters at recommended intervals helps maintain the cleanliness and performance of the fluid and extends the life of the rotary cylinder.

5. Repairs: In the event of major damage or malfunction, rotary cylinders can be repaired. Skilled technicians or authorized service centers can diagnose the issue, disassemble the cylinder, and perform repairs such as welding, re-machining, or replacing damaged parts. It is important to follow proper repair procedures and use appropriate techniques to ensure the cylinder’s integrity and performance.

6. Reconditioning: Rotary cylinders that have undergone extensive use or have been in operation for a long time may benefit from reconditioning. Reconditioning involves thorough inspection, cleaning, and refurbishment of the cylinder to restore its performance and functionality. This process may include repairs, replacement of worn components, and performance testing.

7. Documentation and Guidelines: Manufacturers provide documentation, guidelines, and technical specifications for their rotary cylinders. These resources often include information on maintenance procedures, recommended service intervals, and troubleshooting guidance. Following the manufacturer’s recommendations ensures that maintenance and repairs are carried out correctly.

It is important to note that the extent of repair and maintenance that can be performed on a rotary cylinder may vary depending on factors such as its design, complexity, and availability of spare parts. It is recommended to consult the manufacturer’s documentation or seek assistance from qualified professionals for specific repair and maintenance needs.

What is a rotary cylinder and how does it function in machinery?

A rotary cylinder is a type of actuator used in machinery to convert fluid power into rotational motion. Here’s a detailed explanation:

Function and Operation:

A rotary cylinder is designed to generate rotary or swinging motion in a machine or system. It consists of a cylindrical housing with an internal piston or vane mechanism. The cylinder housing is connected to the machine or system, while the piston or vane is driven by hydraulic or pneumatic pressure.

When fluid pressure is applied to the rotary cylinder, it creates a force that acts on the piston or vane. This force causes the piston or vane to move in a circular or swinging motion, resulting in rotational movement of the output shaft or mechanism connected to the cylinder. The direction and angle of rotation depend on the design and configuration of the rotary cylinder.

Types of Rotary Cylinders:

There are different types of rotary cylinders, including:

- Rack-and-pinion rotary cylinders: These cylinders use a rack and pinion mechanism to convert linear motion into rotary motion. The fluid pressure pushes the piston, which engages with the rack, causing it to rotate the pinion and generate rotary motion.

- Vane rotary cylinders: Vane cylinders use vanes or blades that are pushed outward by fluid pressure, causing the cylinder to rotate. The vanes slide in and out of slots in the rotor, creating the rotary motion.

- Gear rotary cylinders: Gear cylinders employ gears that mesh together to generate rotary motion. Fluid pressure drives the gears, causing them to rotate and transfer the motion to the output shaft.

Applications:

Rotary cylinders find applications in various machinery and industrial systems where rotational movement is required. Some common applications include:

- Rotary indexing tables

- Robotic arms and manipulators

- Material handling equipment

- Conveyor systems

- Machine tools

- Packaging machinery

Rotary cylinders offer advantages such as compact size, high torque output, and precise control over rotational motion. They can be used in both hydraulic and pneumatic systems, depending on the specific requirements of the application.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the selection, installation, and operation of rotary cylinders in machinery.

editor by CX 2023-11-25