Product Description

Product Description

Dryer Cylinder is divided into :Cast Iron Dryer Cylinder,Steel Dryer Cylinder,Yankee Dryer Cylinder

A Yankee dryer cylinder is a pressure vessel used in the production of tissue paper. On the Yankee dryer cylinder, the paper goes from approximately 42-45% dryness to just over 89% dryness. In industry, MG cylinders or Yankee dryers are primarily used to remove excess moisture from pulp that is about to be converted into paper. The Yankee cylinder can be equipped with a doctor blade and sprayed with adhesives to make the paper stick. Creping is done by the Yankee’s doctor blade that is scraping the dry paper off the cylinder surface thereby crêping the paper. The crinkle (crêping) is controlled by the strength of the adhesive, geometry of the doctor blade, speed difference between the yankee and final section of the paper machine and paper pulp characteristics.

All dryer cylinders, heads and journals are made of special cast iron. Separate journals are bolted CHINAMFG the dryer heads. Dryer shells are ground on the outside and turned on the inside. All dryer journals with steam or condensate pipes have insulation sleeves. The inner surfaces have grooves for the stationary siphons. The front side ends of all dryers contain manholes.

Cast iron material are excellent in durability.This is because the free form flake graphite in the cast iron material ensured its high corrosion and erosion resistance. The cast iron also has good fatigue strength under the pressure roller forces. At the same time, cast iron itself has a good surface performance, does not need metal spraying treatment like steel dryer.

Structure of Dryer Cylinder

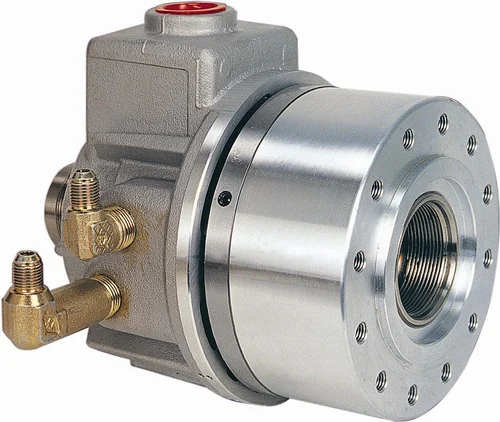

The main parts of the dryer include: Shell,Turbulator bars,Syphon, Shell head,Manhole cover,bearing ,Head cover, Steam Joint .

Heat Transfer

At present, most paper machines use steam heating dryer cylinder to provide heat energy, in the way of heat conduction, heat energy is transferred to the paper through the dryer. The humidity is generally from 60% reduced to 5% when the paper coming out from the dryer section, and then into the glazing machine.

Grooved Internal Surface

We provided grooved internal surfaces Yankee dryer for customer choice. The Grooved Yankee dryer internal face is machined with radial grooves, condensed water accumulates in the grooves during running. It is used with a condensate extractor, each siphon on the extractor is located in the groove so that the condensed water can be effectively discharged. Under the same working condition, the grooved internal surface has good heat transfer efficiency and less steam loss than the smooth internal surface because of the reduced thickness at the root of the shell. This design can be applied to the paper machine’s speed within 2200m/min.

Condensate discharge device

Stationary Siphon

Siphon selection is an important factor to maximize drying rate and reduce temperature variation.

The pressure difference requirement of stationary siphons is relatively low. The pressure difference required for cantilever stationary siphon does not increase with the increase of paper machine speed.

Condensate water can be discharged without use high pressure steam power in the case of air inlet pressure and pressure difference close to or lower than atmospheric pressure, it can reduce the corrosion.

Cantilever stationary siphons are usually suitable for medium to high speed paper machines.

Condensate Extractors & bars

Condensate extractors

The condensate extractors applied on grooved internal surface Yankee dryer cylinder.

It is supported by CHINAMFG structures which ensure the required frame rigidity.

The entire system is designed to compensate thermal expansion and provide high wear resistance.

The turbo bars helps to increase the heat transfer rate by generating resonance waves in the condensate film.

Advantage

1)Applied to smooth internal surface Yankee dryers

2)Increased condensate turbulence

3)Improved heat transfer and drying capacity

4)Improved surface temperature profile

Workshop of dryer cylinder

Technical parameters:

| Diameter | Design Pressure Mpa |

Material | Hardness | Width | Shell Thickness | Roughness | Working speed |

| 1500 | 0.3-0.8 | HT250-300 | 190-240 | 350-10000 | 25-32 | 0.2-0.4 | 200-1200 |

| 1800 | 0.3-0.8 | HT250-300 | 190-240 | 350-10000 | 28-36 | 0.2-0.4 | 200-1200 |

| 2000 | 0.3-0.8 | HT250-300 | 190-240 | 1350-5000 | 30-40 | 0.2-0.4 | 200-1200 |

| 2500 | 0.3-0.8 | HT250-300 | 190-240 | 1350-5000 | 32-47 | 0.2-0.4 | 200-500 |

| 3000 | 0.3-0.8 | HT250-300 | 190-240 | 1350-5000 | 37-56 | 0.2-0.4 | 200-600 |

| 3660 | 0.3-0.8 | HT250-300 | 190-240 | 1350-5000 | 40-65 | 0.2-0.4 | 200-1200 |

| 3680 | 0.3-0.8 | HT250-300 | 190-240 | 1350-5000 | as required | 0.2-0.4 | 200-1200 |

| ≤1500 | 0.3-0.5 | HT200-250 | 190-240 | 1350-5000 | 18-27 | 0.2-0.4 | 200-1200 |

Packing & Shipping

Company Profile

We are a China Based engineering company and machinery supplier committed to offer complate solution and provide high-cost-performance equipments related to stock preparation and paper-making industry.For years,we have insisted on taking customer’s value as our center and having strict quality-control and innovation in the whole process.

With advantage technology and excellent equipment,we provide one-stop service from consultation,process design and optimization,manufacture,installation,commissing and personnel training and so on.At the same time,we can supply all kinds of stock preparation and paper making equipment and accessories.Besides,we can custom design according to customers’ requirements.

Our products have reliable quality and superior performance and have been exported to Poland,Greece,Turkey,Iran,India,Packistan,Bangladesh,Thailand,Indonesia,Philippines,Malaysia,Vietnam,Mexico,Guatemala,Costa Rica,Columbia,Egypt etc.We have established long-term cooperation relationship with many paper mills and agent.

Honesty,cooperation and CHINAMFG are important to us.We insisted on serve our customers with high quality products,sincere service and good reputation.We are appreciated for the long-term trust and favor from our customers.Hope we can cooperate sincerely and make progress together with our new and old customer.

Customer’s satisfaction is our goal !

| After-sales Service: | Online Service |

|---|---|

| Warranty: | 12 Months |

| Certification: | ISO 9001:2008, CE |

| Surface Treatment: | Polishing |

| Manufacturing Process: | Casting |

| Material: | Cast Iron |

| Customization: |

Available

|

|

|---|

How do rotary cylinders contribute to precise rotational control?

Rotary cylinders play a crucial role in achieving precise rotational control in various applications. Here’s a detailed explanation:

1. Actuation Methods: Rotary cylinders utilize hydraulic or pneumatic actuation methods to generate rotational motion. These actuation methods offer precise control over the application of force, allowing for accurate and controlled rotation.

2. Control Valves: Control valves are used to regulate the fluid flow into and out of the rotary cylinder. By adjusting the valve settings, the rotational speed and direction can be precisely controlled, enabling precise rotational control.

3. Feedback Systems: Some rotary cylinders incorporate feedback systems, such as position sensors or encoders, to provide real-time information about the cylinder’s rotational position. This feedback enables precise control over the rotational movement, allowing for accurate positioning and synchronization with other system components.

4. Stroke Adjustment: Rotary cylinders often have adjustable stroke lengths, which allow for precise control over the range of rotational movement. By adjusting the stroke, the rotational angle can be precisely controlled, enabling precise rotational control for specific applications.

5. Positioning Guides: Rotary cylinders may feature positioning guides, such as grooves or slots, that help guide and stabilize the rotational movement. These guides ensure precise alignment and minimize deviations or wobbling during operation, contributing to precise rotational control.

6. Precision Manufacturing: Rotary cylinders are manufactured with high precision to ensure smooth and accurate rotation. The use of high-quality materials, precision machining, and tight tolerances contribute to precise rotational control, minimizing unwanted variations or errors.

7. Integration with Control Systems: Rotary cylinders can be seamlessly integrated with control systems, allowing for precise control over the rotational motion. They can be programmed and synchronized with other system components, such as sensors, actuators, and PLCs, to achieve precise rotational control in complex automation processes.

These factors combined contribute to the precise rotational control achieved through the utilization of rotary cylinders. It’s important to consult manufacturers’ documentation and guidelines for specific information on the capabilities and limitations of rotary cylinders in achieving precise rotational control.

What benefits do rotary cylinders offer in terms of efficient rotary motion?

Rotary cylinders offer several benefits in terms of efficient rotary motion. Here’s a detailed explanation:

1. Compact Design: Rotary cylinders have a compact design, allowing them to be easily integrated into machinery and equipment with limited space. Their compact size ensures efficient utilization of available workspace.

2. High Torque Output: Rotary cylinders are capable of generating high torque output, making them suitable for applications that require powerful rotational force. This enables efficient operation even in heavy-duty tasks.

3. Precise Control: Rotary cylinders provide precise control over rotary motion. By adjusting the fluid pressure or flow rate, the rotational speed and position of the cylinder can be accurately controlled, allowing for precise positioning and smooth operation.

4. Quick Response Time: Rotary cylinders offer quick response times, enabling rapid and dynamic rotary motion. They can start, stop, and change direction swiftly, making them ideal for applications that require fast and precise rotary movements.

5. Versatile Mounting Options: Rotary cylinders come with versatile mounting options, allowing them to be easily mounted in different orientations to suit specific application requirements. This flexibility in mounting facilitates efficient integration into various machinery and equipment designs.

6. Energy Efficiency: Rotary cylinders are designed to be energy-efficient. They consume power only during movement, reducing energy consumption and operating costs. Additionally, the compact design of rotary cylinders minimizes friction losses, further enhancing energy efficiency.

7. Durability and Longevity: Rotary cylinders are built to be durable and withstand demanding operating conditions. They are constructed with high-quality materials and undergo rigorous testing to ensure long service life and reliable performance.

8. Wide Range of Sizes and Configurations: Rotary cylinders are available in a wide range of sizes and configurations to accommodate different application requirements. This versatility allows for efficient selection and customization based on specific load capacities, space constraints, and performance needs.

9. Compatibility with Different Fluids: Rotary cylinders are compatible with various hydraulic or pneumatic fluids, providing flexibility in choosing the most suitable fluid for the application. This compatibility ensures efficient operation and reliable performance.

10. Reduction in Manual Labor: By automating rotary motion, rotary cylinders eliminate the need for manual labor in tasks such as rotating or positioning objects. This reduces human effort, increases productivity, and minimizes the risk of repetitive strain injuries.

Overall, the efficient rotary motion provided by rotary cylinders contributes to improved productivity, enhanced control, energy efficiency, and reliable performance in a wide range of industrial applications.

Can rotary cylinders be used for both rotary motion and linear motion?

No, rotary cylinders are specifically designed for generating rotary motion and are not typically used for linear motion. Here’s a detailed explanation:

Rotary Motion:

Rotary cylinders, also known as rotary actuators, are primarily used to convert fluid power into rotational motion. They are designed to generate torque and rotate around a central axis. The rotational movement can be in a full 360-degree rotation or limited to a specific angle depending on the application and the design of the cylinder.

Linear Motion:

For linear motion, a different type of actuator, such as linear cylinders or linear actuators, is used. Linear cylinders are specifically designed to generate linear motion by extending or retracting a piston rod in a linear path. These actuators are commonly used in applications where straight-line movement is required, such as pushing, pulling, lifting, or sliding objects.

Differences:

The design and internal mechanism of rotary cylinders are optimized for rotational motion, while linear cylinders are designed to provide linear motion. These two types of actuators have different structures and operating principles to fulfill their respective purposes.

While rotary cylinders cannot directly produce linear motion, they can be part of a system that combines both rotary and linear motion. For example, in some applications, a rotary cylinder can be used to generate rotational motion, which is then converted into linear motion using additional mechanisms such as racks, gears, or linkages.

It’s important to choose the appropriate type of actuator based on the desired motion requirements of the specific application. Manufacturers’ documentation and guidelines should be consulted to determine the most suitable actuator for a particular motion requirement.

editor by CX 2023-11-22