Product Description

Parker Telescopic Hydraulic Dump Truck/Trailer Cylinder/Roll-Off hoist

Features

·Parker Seal Division-“Zero-leak” Sealing Package

·100,000 Yield Induction Hardened Chrome Plated Rod as Standard

·Skived and Burnished Tubing

·Hardened Pin-eye Bushings

·Parker”Zero-leak” Internal Bypass Piston Design

·Greater Rod Support

Benefits

·Leak Free Extended Life

·More Resilient to External Damage

·Consistant Quality

·Extends Cylinder Life as Cylinder Wears

·More Efficient/Less Heat

·Resiste rod Deflection and Side Loading

| Part Description | |

| Application | Dump truck, Tipping, Trailer, Underbody, Roll-off Hoist |

| Material of cylinder tube | 45 steel,27SiMn, Carbon steel, Alloy steel, and general seamless steel |

| Seal | Hallite,SKF,NOK,Guarnitec,Parker,and other equivalent brands |

| Coating | Hard Chrome 0.03-0.05mm |

| Temperature | _30°C to |

Why choose us?

Roca team takes all your concerns into consideration to suit your hydraulic cylinder requirements. We work out the best design solution for your application.

Hydraulic cylinders are the most effective and efficient method of pushing, pulling, lifting, and lowering.

Nowadays hydraulic cylinders play an essential role in daily application and industry:

√ Mining

√ Earthmoving & Construction

√ Agriculture &Forestry

√Waste Management & Material Handing

√Ship crane & offshore

Selecting the right cylinders for an application is critical in obtaining maximum performance and reliability.

ROCA team takes all your concerns into consideration to suit your hydraulic cylinder requirements.

Together, we work out the best design solution for your application.

FAQ

Q1.Do you have MOQ?

Depending on different ideas, Can be negotiated. The larger the quantity is, the competitive the unit price will be.

Q2.Should the customer pay the delivery fee, How much is it?

For the delivery fee, many samples are being requested to be sent, so we must get the delivery fee.

If you tell me to use the appointed Express, you will give me your express account or you will pay according to the Express.

If you do not request, I will choose a cheap one in China.

Q3.How about the after sale service?

1) We will always keep the quality the same as the buyer’s samples and if there is something with the quality, we will make compensation for our customers.

2) We will suggest our packing and take charge in our packing, we will keep the goods safe in the delivery.

3) We will trace the goods from the production to selling, we will solve the problems in the selling for our customers.

Q4.When can I get a price?

We usually quote within 24 hours after we get your inquiry.

Q5: Are you a trade company or manufacturer?

We are a professional manufacturer with our own factory.

| Certification: | RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | High Temperature |

| Acting Way: | Single Acting |

| Working Method: | Rotary |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How do rotary cylinders contribute to precise rotational control?

Rotary cylinders play a crucial role in achieving precise rotational control in various applications. Here’s a detailed explanation:

1. Actuation Methods: Rotary cylinders utilize hydraulic or pneumatic actuation methods to generate rotational motion. These actuation methods offer precise control over the application of force, allowing for accurate and controlled rotation.

2. Control Valves: Control valves are used to regulate the fluid flow into and out of the rotary cylinder. By adjusting the valve settings, the rotational speed and direction can be precisely controlled, enabling precise rotational control.

3. Feedback Systems: Some rotary cylinders incorporate feedback systems, such as position sensors or encoders, to provide real-time information about the cylinder’s rotational position. This feedback enables precise control over the rotational movement, allowing for accurate positioning and synchronization with other system components.

4. Stroke Adjustment: Rotary cylinders often have adjustable stroke lengths, which allow for precise control over the range of rotational movement. By adjusting the stroke, the rotational angle can be precisely controlled, enabling precise rotational control for specific applications.

5. Positioning Guides: Rotary cylinders may feature positioning guides, such as grooves or slots, that help guide and stabilize the rotational movement. These guides ensure precise alignment and minimize deviations or wobbling during operation, contributing to precise rotational control.

6. Precision Manufacturing: Rotary cylinders are manufactured with high precision to ensure smooth and accurate rotation. The use of high-quality materials, precision machining, and tight tolerances contribute to precise rotational control, minimizing unwanted variations or errors.

7. Integration with Control Systems: Rotary cylinders can be seamlessly integrated with control systems, allowing for precise control over the rotational motion. They can be programmed and synchronized with other system components, such as sensors, actuators, and PLCs, to achieve precise rotational control in complex automation processes.

These factors combined contribute to the precise rotational control achieved through the utilization of rotary cylinders. It’s important to consult manufacturers’ documentation and guidelines for specific information on the capabilities and limitations of rotary cylinders in achieving precise rotational control.

Can rotary cylinders be used in manufacturing machinery for indexing?

Yes, rotary cylinders can be used in manufacturing machinery for indexing. Here’s a detailed explanation:

Indexing refers to the precise positioning of components, workpieces, or tools at specific intervals or angles in manufacturing processes. Rotary cylinders are well-suited for indexing applications due to their ability to provide controlled and precise rotational motion. Here’s how they are used:

1. Rotary Motion Generation: Rotary cylinders convert fluid power, either hydraulic or pneumatic, into rotary motion. By controlling the flow of fluid into and out of the cylinder, the rotary motion can be accurately regulated. This controlled rotation is essential for indexing applications where precise angular positioning is required.

2. Angular Displacement: Rotary cylinders enable angular displacement with high accuracy. They can rotate a component or workpiece to a specific angle or index it at precise intervals. This capability is crucial in manufacturing processes that involve operations such as cutting, drilling, assembly, or inspection at specific angular positions.

3. Positioning Accuracy: Rotary cylinders offer excellent positioning accuracy, allowing for precise indexing. By combining precise control of fluid flow with position feedback devices such as rotary encoders or potentiometers, the cylinder can accurately reach and maintain specific angular positions. This level of positioning accuracy ensures that indexing operations are performed with high precision and repeatability.

4. Speed and Acceleration Control: Rotary cylinders provide control over the rotational speed and acceleration, enabling smooth and gradual indexing movements. By adjusting the fluid flow rate or pressure, the rotational velocity and acceleration can be precisely controlled. This feature is particularly beneficial in indexing applications that require gradual start-up or deceleration to prevent abrupt movements or damage to the workpiece.

5. Compact and Lightweight Design: Rotary cylinders are often designed to be compact and lightweight, making them suitable for integration into manufacturing machinery. Their compact size allows for efficient use of space, while their lightweight nature reduces rotational inertia and enables faster response times. These design characteristics contribute to the overall efficiency and performance of indexing operations.

6. Integration with Control Systems: Rotary cylinders can be seamlessly integrated into control systems such as programmable logic controllers (PLCs) or computer numerical control (CNC) systems. This integration enables precise coordination and synchronization of the rotary motion with other machine operations, ensuring accurate indexing within the overall manufacturing process.

7. Customization: Manufacturers offer a wide range of rotary cylinder models with different sizes, load capacities, and performance characteristics. This allows users to select the most suitable cylinder for their specific indexing application. Customization options further enhance the ability to tailor the cylinder’s performance to meet specific indexing requirements.

8. Compatibility with Machine Tools: Rotary cylinders can be integrated with machine tools used in manufacturing processes. They can be coupled with indexing tables, rotary stages, or tool turrets to achieve precise angular positioning and indexing of workpieces or tools. This integration enhances the versatility and functionality of the manufacturing machinery.

By incorporating these features, rotary cylinders contribute to efficient and accurate indexing in manufacturing machinery, enabling precise positioning and synchronization of components or tools in various industrial processes.

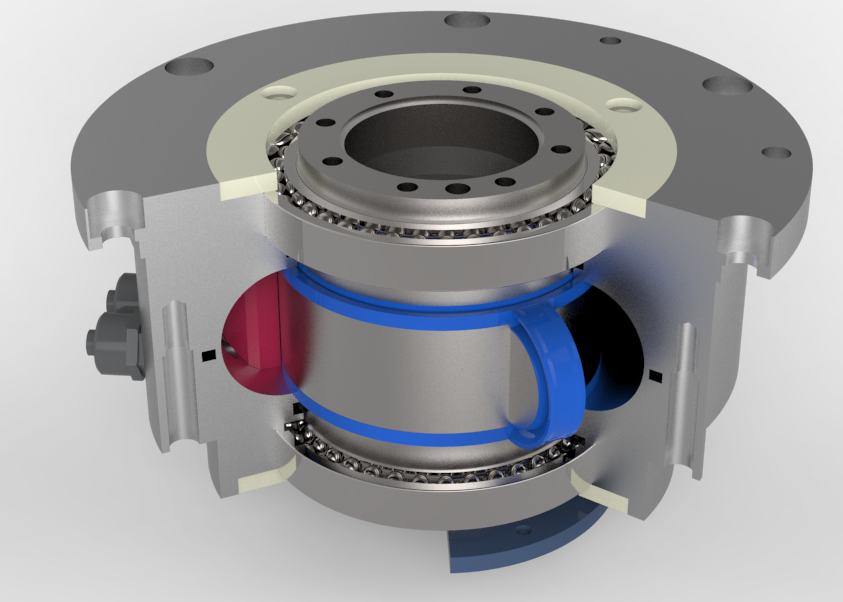

What are the key components and design features of a rotary cylinder?

A rotary cylinder consists of several key components and design features that enable its operation. Here’s a detailed explanation:

Key Components:

1. Housing: The housing is a cylindrical structure that encloses the internal components of the rotary cylinder. It provides support and protection to the internal mechanisms.

2. Piston or Vane: The piston or vane is the component that converts fluid pressure into rotary motion. In rack-and-pinion rotary cylinders, the piston engages with a rack to generate rotation. In vane or gear rotary cylinders, the piston or vane is responsible for creating the rotary motion directly.

3. Seals: Seals are used to prevent leakage of fluid and maintain pressure within the cylinder. They are typically made of rubber or other materials that provide a tight and reliable seal.

4. Bearings: Bearings are used to support the rotating components and reduce friction. They ensure smooth and efficient movement of the piston or vane within the cylinder.

Design Features:

1. Mechanism Type: Rotary cylinders can have different mechanism types, such as rack-and-pinion, vane, or gear mechanisms. The choice of mechanism depends on factors such as the required torque, speed, and application requirements.

2. Mounting Options: Rotary cylinders may have various mounting options to facilitate their installation and integration into different machinery or systems. Common mounting options include flange mounts, foot mounts, and trunnion mounts.

3. Fluid Connections: Rotary cylinders require fluid connections to supply hydraulic fluid or compressed air for their operation. These connections allow the cylinder to receive and release the fluid as needed to generate the rotary motion.

4. Motion Control: Some rotary cylinders may feature additional components for motion control, such as position sensors or limit switches. These components allow for precise control and monitoring of the rotary motion, enabling automation and system feedback.

5. Size and Capacity: Rotary cylinders come in various sizes and capacities to accommodate different application requirements. The size and capacity of a rotary cylinder determine its torque output, speed capabilities, and overall performance characteristics.

6. Material Selection: The materials used in the construction of a rotary cylinder are chosen based on factors such as strength, durability, and compatibility with the operating environment. Common materials include steel, aluminum, and various alloys.

Overall, the key components and design features of a rotary cylinder work together to convert fluid power into rotary motion efficiently and reliably. These components and features ensure smooth operation, precise control, and the ability to meet the demands of specific applications.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the components, design, and maintenance of rotary cylinders.

editor by CX 2023-10-26