Product Description

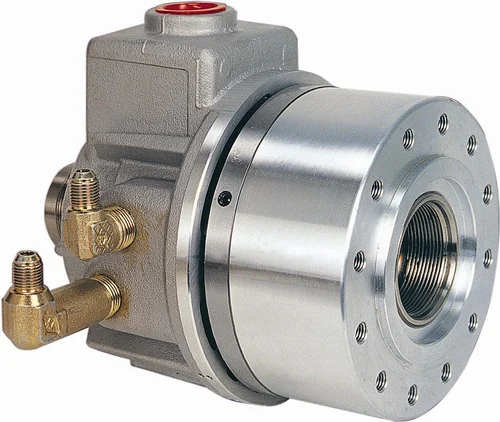

High Quality OEM Brand Single Rotary Cylinder CDRB2B Series Vane Type Pneumatic Swing Cylinder CDRB2BW-40

Product Description

Features:

1.CRB2BW series rotary Rotary Actuators .

2.Equivalent to CHINAMFG series rotary Rotary Actuators , with the same appearance.

3.Bore size(mm): 10, 15, 20, 30.40

4.Double piston, Compact, Rack & Pinion style rotary actuator.

5.Angle adjustment is possible.

6.A wide variety of types and broad size variations.

Recommend products

Company Profile

Application scenarios

FAQ

1. who are we?

We are a professional manufacturer with more than 9 years experience

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Mechanical Parts

4. why should you buy from us not from other suppliers?

1. The company integrates research and development, production and sales as an integrated business model, which greatly reduces

consumers’ purchase of finished products. 2. Short production time and quick cycle of large goods. 3. Professional after-sales

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,HKD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese

| Material: | Aluminum |

|---|---|

| Usage: | Print, Semiconductor, Automation and Control, Robot |

| Structure: | Piston Cylinder |

| Power: | Pneumatic |

| Standard: | Standard, Nonstandard |

| Pressure Direction: | Double-acting Cylinder |

| Samples: |

US$ 95/Piece

1 Piece(Min.Order) | |

|---|

Can rotary cylinders be customized for specific machinery and equipment?

Yes, rotary cylinders can be customized to meet the specific requirements of different machinery and equipment. Here’s a detailed explanation:

1. Mounting Options: Rotary cylinders can be customized with various mounting options to ensure seamless integration with specific machinery and equipment. Different mounting styles, such as flange mounts, foot mounts, or clevis mounts, can be provided to accommodate the mounting needs of the application.

2. Shaft Configurations: Rotary cylinders can be customized with different shaft configurations to suit specific machinery and equipment designs. The shaft can be extended or modified to match the required dimensions, keyways, or connections necessary for the intended application.

3. Stroke Length: The stroke length of rotary cylinders can be customized to meet the specific range of rotational motion required by the machinery or equipment. By adjusting the stroke length, the rotary cylinder can be tailored to provide the desired angular movement.

4. Sealing Options: Rotary cylinders can be customized with various sealing options to ensure compatibility with different operating environments. Different types of seals, such as nitrile, Viton®, or polyurethane seals, can be used based on factors like temperature, pressure, and the presence of corrosive or abrasive substances.

5. Special Features: Depending on the application requirements, rotary cylinders can be customized with special features. This may include the integration of position sensors, encoders, or limit switches to provide feedback and enhance control. Additionally, custom ports, fittings, or connections can be added to facilitate the integration of the cylinder into the specific machinery or equipment.

6. Material Selection: The materials used in the construction of rotary cylinders can be customized based on factors such as the operating environment, load requirements, or chemical compatibility. Custom material selection ensures the cylinder’s durability and performance in the specific machinery and equipment.

7. Performance Parameters: Rotary cylinders can be customized to meet specific performance parameters, such as torque output, rotational speed, or response time. By adjusting the internal design and components, the cylinder’s performance can be optimized for the particular machinery or equipment.

It’s important to collaborate with manufacturers or suppliers who specialize in customizing rotary cylinders for specific machinery and equipment. They can provide guidance and expertise in tailoring the cylinder to meet the precise requirements of the application.

How do rotary cylinders handle variations in environmental conditions?

Rotary cylinders are designed to handle variations in environmental conditions encountered in different applications. Here’s a detailed explanation:

1. Robust Construction: Rotary cylinders are constructed using durable materials such as high-grade metals, alloys, and seals that can withstand harsh environmental conditions. They are designed to resist factors like vibration, shock, temperature variations, dust, moisture, and exposure to corrosive substances. The robust construction ensures that rotary cylinders can operate reliably and maintain performance integrity in challenging environments.

2. Sealing Mechanisms: Rotary cylinders incorporate sealing mechanisms to prevent the ingress of contaminants such as dirt, water, and chemicals. These sealing mechanisms include O-rings, wipers, and lip seals, which create a barrier between the cylinder’s internal components and the external environment. Effective sealing helps protect the cylinder’s internal parts, ensuring smooth operation and preventing damage caused by environmental factors.

3. Lubrication Systems: Proper lubrication is essential for the smooth functioning of rotary cylinders. They are equipped with lubrication systems that deliver lubricants to critical moving parts, reducing friction, wear, and the risk of corrosion. Lubrication systems can be designed to operate under different environmental conditions, ensuring optimal performance and longevity of the cylinder.

4. Temperature Compensation: Rotary cylinders can be designed with temperature compensation features to accommodate variations in operating temperatures. When exposed to high or low temperatures, materials can expand or contract, potentially affecting the cylinder’s performance. Temperature compensation mechanisms, such as thermal expansion compensation or heat dissipation features, help maintain the cylinder’s dimensional stability and performance in different temperature conditions.

5. Protective Coatings: In environments where there is a high risk of corrosion or abrasion, rotary cylinders can be coated with protective layers or treatments. These coatings, such as corrosion-resistant plating, powder coatings, or specialized coatings for specific applications, provide an additional barrier against environmental factors and extend the cylinder’s lifespan.

6. Environmental Testing: Manufacturers subject rotary cylinders to rigorous testing procedures to ensure their performance and reliability under various environmental conditions. These tests may include temperature cycling, humidity exposure, dust and particle ingress testing, vibration testing, and salt spray testing. Environmental testing helps identify potential weaknesses and allows for improvements in design and materials to enhance the cylinder’s ability to handle environmental variations.

7. IP Ratings: In industrial applications, rotary cylinders are often assigned an Ingress Protection (IP) rating. IP ratings indicate the level of protection against solid particles (first digit) and moisture (second digit) that the cylinder can withstand. Higher IP ratings signify greater resistance to environmental factors. Users can select rotary cylinders with appropriate IP ratings based on the specific environmental conditions of their application.

8. Application-Specific Designs: Depending on the industry and application requirements, rotary cylinders can be designed with specific environmental considerations in mind. For example, in marine or offshore applications, cylinders can be corrosion-resistant and designed to withstand saltwater exposure. In dusty environments, additional filtration systems can be incorporated to prevent dust ingress. Customized designs allow rotary cylinders to handle variations in environmental conditions effectively.

By incorporating these features and design considerations, rotary cylinders can effectively handle variations in environmental conditions, ensuring reliable performance and longevity in diverse applications.

What are the key components and design features of a rotary cylinder?

A rotary cylinder consists of several key components and design features that enable its operation. Here’s a detailed explanation:

Key Components:

1. Housing: The housing is a cylindrical structure that encloses the internal components of the rotary cylinder. It provides support and protection to the internal mechanisms.

2. Piston or Vane: The piston or vane is the component that converts fluid pressure into rotary motion. In rack-and-pinion rotary cylinders, the piston engages with a rack to generate rotation. In vane or gear rotary cylinders, the piston or vane is responsible for creating the rotary motion directly.

3. Seals: Seals are used to prevent leakage of fluid and maintain pressure within the cylinder. They are typically made of rubber or other materials that provide a tight and reliable seal.

4. Bearings: Bearings are used to support the rotating components and reduce friction. They ensure smooth and efficient movement of the piston or vane within the cylinder.

Design Features:

1. Mechanism Type: Rotary cylinders can have different mechanism types, such as rack-and-pinion, vane, or gear mechanisms. The choice of mechanism depends on factors such as the required torque, speed, and application requirements.

2. Mounting Options: Rotary cylinders may have various mounting options to facilitate their installation and integration into different machinery or systems. Common mounting options include flange mounts, foot mounts, and trunnion mounts.

3. Fluid Connections: Rotary cylinders require fluid connections to supply hydraulic fluid or compressed air for their operation. These connections allow the cylinder to receive and release the fluid as needed to generate the rotary motion.

4. Motion Control: Some rotary cylinders may feature additional components for motion control, such as position sensors or limit switches. These components allow for precise control and monitoring of the rotary motion, enabling automation and system feedback.

5. Size and Capacity: Rotary cylinders come in various sizes and capacities to accommodate different application requirements. The size and capacity of a rotary cylinder determine its torque output, speed capabilities, and overall performance characteristics.

6. Material Selection: The materials used in the construction of a rotary cylinder are chosen based on factors such as strength, durability, and compatibility with the operating environment. Common materials include steel, aluminum, and various alloys.

Overall, the key components and design features of a rotary cylinder work together to convert fluid power into rotary motion efficiently and reliably. These components and features ensure smooth operation, precise control, and the ability to meet the demands of specific applications.

It’s important to consult the manufacturer’s documentation and guidelines for specific information on the components, design, and maintenance of rotary cylinders.

editor by CX 2023-10-13